الحار منتجات

ملكنا الإخبارية

3 8m×13 Cement Mill

3.8 * 13m Ball Mill for Cement Plant - China Ball Mill and Cement Mill

3.8 * 13m Ball Mill for Cement Plant, Find Details and Price about Ball Mill Cement Mill from 3.8

获取价格

3.8*13 m Cement ball mill

2021/12/6 3.8*13 m Cement ball mill. No reviews yet. Henan Hongke Heavy Machinery

获取价格

3.8*13m Center Double Sliding Dry Cement Ball Mill From Molly

3.8*13m Center Double Sliding Dry Cement Ball Mill From Molly. Production Capacity:0.65

获取价格

Cement Mill Test Report - Argos US

2021/7/8 M85 and ASTM C150 specifications for Type I Cement. Certified By: Argos USA LLC - Tampa Plant 2001 Maritime Blvd _____ (8 13) 247-4831 Tampa, FL 33605 Quality Coordinator Report created: 7/8/2021 Cement Mill Test Report White Type I Cement ASTM C150 and AASHTO M85 Standard Requirements

获取价格

Cement plant projects of pre-grinding equipment

Cement mill: Specification: Φ1.2×4.5m Open circuit: Φ1.5×5.7m Open circuit: Φ1.83×6.1m Open circuit: ... into a high wind combined fine dynamic classifier (spindle motor power of 200 kW, output 180 t/h ~ 260 t/h) + Φ 3.8 m * 13 m

获取价格

C E M E N T CEMENT MILL TEST REPORTS: What producers

3; (4) calcium oxide, CaO; (5) magne-sium oxide, MgO; (6) sulfur trioxide, SO 3; (7) sodium oxide, Na 2 O; and (8) potassium oxide, K 2 0. Cements with a higher Fe 2 O 3 c o n - tent tend to be darker as a rule. For ex-ample, a cement with an Fe 2 O 3 c o n - tent of 3.8% is often darker than a cement with an Fe 2 O 3 content of 3.0%. C E M E N ...

获取价格

Use Cement Ball Mill Grinding Cement Clinker Cement Ball Mill

The φ3.8×13 cement ball mill with double-sliding structure solves the problem of the similar product “the discharge end slide bearing temperature is too high to operate continuously”, which ensures the equipment can run continuously and stably for a long time and makes a new technical breakthrough in the field of double slide ball mill.

获取价格

Mill drives Up to 25 MW, 13.8 kV - MENZEL Elektromotoren

Up to 25 MW, 13.8 kV. German manufacturer since 1927. More than 10000 References worldwide. Your global supplier for large industrial motors Menu Home. Electric motors Open Submenu. Electric motors ... Slip-ring motor for cement mill in IM 1101 design . 6600 V Slip ring (IC 611 + IC 616 + IC 666) Mill drives. learn more.

获取价格

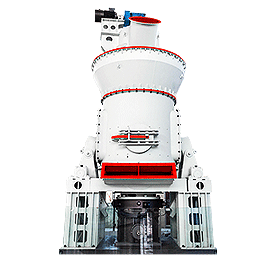

Cement Mill Vertical Mill Manufacturer SINOMALY

SINOMALY provides various types of cement mills, which can be matched with grinding mill production line with output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d.

获取价格

CEMENT FORMULAE HANDBOOK - Green Business Centre

13 Ball Mill - Study Data 105 14 Ball Mill Formulas 111 15 BIS Specification of Additives 113 16 Cement Testing 115 17 BIS Specifications for various Cements 120 18 Thermo Physical Properties of Different Insulating Materials 124 ... (3-7days) in the cement 3. Alumina Modulus/Alumina iron ratio (AM) AM = Al 2O 3 Fe 20 3 Typical Range : 1.0 ...

获取价格

Air Swept Coal Mill - Cement Plant Equipment Coal Grinding Mill

Air-swept coal mills produced by AGICO CEMENT have 13 models according to their cylinder sizes. The diameter and length are between Φ1200×2400-Φ2900×4700 (mm), and the matching motor power is 45-570KW, which can meet 1.4- 16 t/h pulverized coal production.

获取价格

Cement mill - Wikipedia

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

获取价格

Cement Separator Ball Mill Optimization

Mill performance test. Steps 1. Recording of related operational data 2. Air flow measurement 3. Crash stop and visual inspection in mill 4. Sampling in mill 5. Evaluation of test . 1. Recording of related operational data-Tube Mill. Feed rate, Return, Grinding aids, Water injection, Mill drive power (kW)-Static separator Vane position-Mill ...

获取价格

OK™ CEMENT MILL

finish grinding of Portland cement, slag and blended cements. The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 30-45 percent lower for cement grinding and 40-50 percent lower for slag. The ...

获取价格

Cement Equipment Export Performance PENGFEI Group

φ2.4×8m cement mill: Silica sand mill: Germany German IVA Company: φ3.4×6m mill, used for grinding non-metal ores ... including 3.5×13m mill, eight-mouth cement packaging machine, etc. 1: Kenya Kenya jiaoji Chemical Co., Ltd. ... φ4×13 cement mill complete set of equipment for grinding station: 1:

获取价格

Separators in the cement industry - thecementgrindingoffice

Problems of the cement mill can disturb the performance of the separator - Uncommon circuit thecementgrindingoffice 7.10 Special designs for raw mill circuits: ... 173333 divided by 3600 divided by 13 = 3,7 m/sec (it is OK because < 4 m/sec) - Different solutions are possible in function of the customer wishes: - O'Sepa N-3000 ...

获取价格

Cement plant operations handbook for dry process plants :

-13. Cementquality-14. Settingtime-15. ASTMcement types andspecifications-16. European EN 197 cementspecification-17. Compositecements (intergrinds)-18. ... Kiln specific fuel consumption 3. Cement mill specific powerconsumption 4. Othersystems-5. Debottlenecking 6. Projectaudit 7. Riskassessment 14. Plantassessmentlist 202 1. General-2.

获取价格

OK™ CEMENT MILL

finish grinding of Portland cement, slag and blended cements. The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 30-45 percent lower for cement grinding and 40-50 percent lower for slag. The ...

获取价格

Cement Equipment Export Performance PENGFEI Group

φ2.4×8m cement mill: Silica sand mill: Germany German IVA Company: φ3.4×6m mill, used for grinding non-metal ores ... including 3.5×13m mill, eight-mouth cement packaging machine, etc. 1: Kenya Kenya jiaoji Chemical Co., Ltd. ... φ4×13 cement mill complete set of equipment for grinding station: 1:

获取价格

Separators in the cement industry

Problems of the cement mill can disturb the performance of the separator - Uncommon circuit thecementgrindingoffice 7.10 Special designs for raw mill circuits: ... 173333 divided by 3600 divided by 13 = 3,7 m/sec (it is OK

获取价格

Cement plant operations handbook for dry process plants :

-13. Cementquality-14. Settingtime-15. ASTMcement types andspecifications-16. European EN 197 cementspecification-17. Compositecements (intergrinds)-18. ... Kiln specific fuel consumption 3. Cement mill specific powerconsumption 4. Othersystems-5. Debottlenecking 6. Projectaudit 7. Riskassessment 14. Plantassessmentlist 202 1. General-2.

获取价格

Analysis of the efficiency of the grinding process in closed

ball mill open and closed circuits [12] with the installation in all cases the dynamic separator. When transferring to closedcircuit а mill size 2.6×13 m at a constant quality cement (3000 cm2pg) capacity grinding unit was increased from 25 to 38 tph while reducing the specific consumption of electricity from 41.6 to 29.3 kWhpt. The parameter

获取价格

The Cement Plant Operations Handbook - International

Finish mill – 12. Cement – 13. Quality control – 14. Packing and distribution – 15. Emission abatement (dust, NO x, SO 2, etc) – 16. Maintenance – 17. Process – 18. Materials analysis –19. Plant capacity summary – 20. Storage capacity 15. Cement plant construction and valuation 244 1. New plant construction – 2.

获取价格

Cement mill PDF - SlideShare

2017/1/12 Cement mill - Download as a PDF or view online for free ... - 8/1430 1600 740 JDX1000 7.15 213 Φ3.5×13 17.5 ≤25 50~60 150 YR2000- 8/1730 2000 740 JDSX1000 6.3 240.5 Φ3.8×13 16.3 ≤25 65~70 185 YR2500- 8/1730 2500 740 JS130-C-F1 220 Φ4×13 16.3 ≤2 78~80 191 YRKK900 2800 745 JS140-A 200 Φ4.2×11 15.6 ≤2 120~140 190 YR2800- 8/ ...

获取价格

a) Cement ball mill view, b) Cement mill sketch.

Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two ...

获取价格

Analysis of material flow and consumption in cement

2016/1/20 Over the last century, Portland cement-based concrete has become the highest manufactured product on Earth in terms of volume. Concrete is used worldwide as a building material and is the most consumed substance on Earth after water (Sakai, 2009).The volume of concrete produced globally is approximately 5.30 billion m 3 per year (Roskos et al., 2011),

获取价格

Ball Mill - thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.. Used in combination with the sepol® high-efficiency separator, ball mills can reliably

获取价格

OK Mill: The 3: Mechanical optimized and 3.1: Grinding

In Figure 3, two vertical mill types are compared running on the same plant and fed with the same clinker, clearly showing the significant energy efficiency benefit with the OK mill. Figure 3: VRMs for cement - OK (lower line) and flat bed (upper line) mill system power consumption, including mill, fan and separator.

获取价格

Ball Mill Design/Power Calculation - LinkedIn

2016/12/12 cement ball mill May 13, 2022 Graphite Rotary Dryer Feb 12, 2022 flotation separation process Sep 24, 2021 No more next content See all. Insights from the community ...

获取价格

Cement Silo Solution for Cement Storage

For cement silios above 50T, we recommend detachable bolted type due to its advantage of money-saving during transportation. Cement silo parts: The cement bin (cement tank) consists of: steel structure part, ladder, guardrail, loading pipe, dust collector, pressure relief valve, high and low material level gauge, unloading valve, etc.

获取价格

Vertical Cement Mill, Vertical Roller Mill Buy Cement ... - Cement

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind

获取价格سنگ شکن قابل حمل سنگ برای استخدام شرکت za در آفریقای جنوبی

جوال بيلي ميسين كسارة الحجر

كسارات باركر 90100120

ف المرجل في مطحنة الأسمنت whr

الحزام الناقل للفحم الجزائر

لفة مطحنة الصور صغيرة الحجم

فرط نوع الضغط ضد مطحنة مسحوق

مطحنة طحن مع عملية الرطب

شراء غسيل الرمال سعر الجهاز

كيفية صنع سماد رملي في السنهالية

كسارة Orissa lomedtone daerah

إنجازات الرئيس المطاحن

الرئيسية الفك كسارة الفك الأسهم

استخراج المعدن من خام في مخطط التدفق

سحق الصابورة طحن

كسارة الخفاف المحمولة للبيع في الأردن

آلة غسل الرمل اللولبية ذات السعة الكبيرة

التكلفة النموذجية للتكسير الكلي في الموقع

وظائف معدات سحق الفك والمخروط الحجر

مطحنة الجرانيت Kolkata laos

كيفية بيع 2400 كسارة مخروطية

تقرير مشروع معدات تكسير الحجارة للأمير

cost of mercial silica sand washing machine

مطحنة الكرة للبيع غالون

پردازش قیمت کارخانه

تأثير الصخور محطم pf 1210 رسومات

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20