الحار منتجات

ملكنا الإخبارية

wear resistance metals

Recent Progress on Wear‐Resistant Materials: Designs, Properties,

2021/3/24 The grain size reduced from 47.54 µm of pure Ni metals to 7.58 µm of the

获取价格

Wear-Resistant Metals and Composites SpringerLink

2021/7/11 The wear-resistance materials are customarily made by the introduction of

获取价格

Recent advances in wear-resistant steel matrix composites: A

2024/3/1 Steel wear-resistant materials (SW-RMs) such as high manganese steel, ...

获取价格

Steel - Wear-Resistant, Alloy, Hardening Britannica

2024/11/19 Steel - Wear-Resistant, Alloy, Hardening: Another group is the wear-resistant steels, made into wear plates for rock-processing machinery, crushers, and power shovels. These are austenitic steels that contain about

获取价格

Why Certain Metals Offer Greater Wear Resistance

2020/11/30 Or that for seawater corrosion. Or this other one for a high wear application. But what about the alloy actually makes it deliver that performance? In this installment, we will explore some simplified technical

获取价格

Wear-Resistant Steel - McMaster-Carr

Choose from our selection of wear-resistant steel, including carbon steel, alloy steel, and more. In stock and ready to ship. BROWSE CATALOG. Abrading Polishing; Building Grounds; ... Specialty Metals Compliant (252.225-7008) Specialty Metals Compliant (252.225-7009) Specialty Metals COTS-Exempt. Not Specialty Metals Compliant. RoHS ...

获取价格

Wear Resistance vs. Hardness Which is Better? - SilcoTek

2021/1/15 The difference between wear resistance and hardness when comparing coating performance. How hardness is measured and calculated. How wear resistance is measured and calculated. When to specify wear resistance vs. hardness when selecting a coating. In a follow-on blog we'll discuss comparative results of wear and hardness tests.

获取价格

Wear-Resistant Metals and Composites - Springer

Wear-Resistant Metals and Composites 5. resistance energy. Powder metallurgy is a technique which may be preferred over other fabrication technique because: † It could produce “near-net shape” components. † More volume fractions of the dispersed material could be incorporated.

获取价格

Wear Resistance - AMPCO METAL

The wear resistance of a material indicates how resistant an alloy is to this process. The more wear-resistant an alloy, the less quickly it loses material from its surface. As wear is one of the main reasons for downtimes, using wear-resistant materials can increase productivity in steel mills and other industries. Strictly speaking, wear is ...

获取价格

Recent advances in wear-resistant steel matrix composites: A

2024/3/1 Steel wear-resistant materials (SW-RMs) such as high manganese steel, ... Improved tool wear properties in sheet metal forming using Carbide Steel, a novel abrasion resistant cast material. Wear, 271 (2011), pp. 1280-1287. View PDF View article View in Scopus Google Scholar [9]

获取价格

Top 10 Metals That Can Withstand Extreme Heat: A Guide to High ...

2024/10/14 It is heavy, dense, and possesses excellent thermal conductivity and high resistance to wear. Key Properties. Melting Point: 3,422°C (6,192°F) ... When selecting a heat-resistant metal, it’s essential to consider not only its melting point but also its creep resistance, oxidation resistance, and other factors like corrosion and electrical ...

获取价格

Wear in Metals - SpringerLink

2024/3/30 The wear resistance of a number of metals, such as titanium, copper, and cadmium, has been investigated in terms of their strain rate characteristics . Wear on hard surfaces is the deterioration, gradual removal, or deformation of the substance. Wear can have mechanical (also known as erosion) or chemical (commonly known as corrosion) causes.

获取价格

Most wear-resistant metal alloy in the world - ScienceDaily

2018/8/16 A materials science team has engineered a platinum-gold alloy believed to be the most wear-resistant metal in the world. It's 100 times more durable than high-strength steel, making it the first ...

获取价格

Wear - Wikipedia

Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. ... An attrition test is a test that is carried out to measure the resistance of a granular material to wear. Modeling of wear. The Reye–Archard–Khrushchov wear law is the classic wear prediction model ...

获取价格

Refractory metals - Wikipedia

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear.The expression is mostly used in the context of materials science, metallurgy and engineering.The definition of which elements belong to this group differs. The most common definition includes five elements: two of the fifth period (niobium and molybdenum) and three of the sixth period

获取价格

Most wear-resistant metal alloy in the world engineered at

2018/8/16 Sandia’s materials science team has engineered a platinum-gold alloy believed to be the most wear-resistant metal in the world. It’s 100 times more durable than high-strength steel, making it the first alloy, or combination of metals, in the same class as diamond and sapphire, nature’s most wear-resistant materials. ...

获取价格

What is wear? – Causes and types - AMPCO METAL

2020/3/26 The more wear-resistant a metal is, the less quickly it loses material from its surface - even if there is friction with another metal. There are several ways to increase the wear resistance of a metal. On the one hand, in certain machines it is possible to install a so-called wear part. This is easy to replace and not too expensive to purchase.

获取价格

Wear - Wikipedia

Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. ... An attrition test is a test that is carried out to measure the resistance of a granular material to wear. Modeling of wear. The Reye–Archard–Khrushchov wear law is the classic wear prediction model ...

获取价格

Refractory metals - Wikipedia

Refractory metals are a class of metals that are extraordinarily resistant to heat and wear.The expression is mostly used in the context of materials science, metallurgy and engineering.The definition of which elements belong to this

获取价格

Most wear-resistant metal alloy in the world engineered at

2018/8/16 Sandia’s materials science team has engineered a platinum-gold alloy believed to be the most wear-resistant metal in the world. It’s 100 times more durable than high-strength steel, making it the first alloy, or combination of metals, in the same class as diamond and sapphire, nature’s most wear-resistant materials. ...

获取价格

What is wear? – Causes and types - AMPCO METAL

2020/3/26 The more wear-resistant a metal is, the less quickly it loses material from its surface - even if there is friction with another metal. There are several ways to increase the wear resistance of a metal. On the one hand, in certain machines it is possible to install a so-called wear part. This is easy to replace and not too expensive to purchase.

获取价格

Wear and enhancement of wear resistance – A review

2020/1/1 Though the metals have good wear resistance but the extremities of inflight environmental conditions and high speed of aircraft cause heavy pitting action and wear on the surface of wings. Thus the material selection for the wing surface becomes very crucial. The field of wear and wear resistance of aircraft wings and similar components thus ...

获取价格

surfacing for wear resistance 1 - Total Materia

The alloys in this group exhibit better impact, erosion resistance, metal-to-metal wear, and shock resistance than the previous groups. The 3B grouping will withstand elevated temperatures of up to 540°C (1000°F). The 3C group is high in cobalt which improves high-temperature properties. The Group 3 alloys are more expensive than Groups 1 and 2.

获取价格

(PDF) Recent Progress on Wear‐Resistant Materials

2021/3/24 This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear‐resistant materials, starting with an introduction of various advanced ...

获取价格

Material Applications: Wear Resistance - MetalTek

2020/11/24 Other wear applications involve abrasive or sliding wear due to a material flowing across the metal being worn; examples of this would be material conveyors, drag lines, mining crushers, etc. In these applications, material hardness is often a key determinant in the final wear resistance of the base metal.

获取价格

Recent Progress on Wear‐Resistant Materials: Designs,

There has been tremendous interest in the development of different innovative wear‐resistant materials, which can help to reduce energy losses resulted from friction and wear by ≈40% over the next 10–15 years. ... In this work, matrix strengthening refers to strategies in the improvement of the wear resistance of bulk metals, ceramics, or ...

获取价格

ARMET - USA Strongest Wear Parts Alloys

The new nickel-free wear-resistant ISC alloy, based on high-chromium cast iron, simultaneously features increased strength, ductility and wear-resistance. It also has good casting properties, is insensitive to overheating before tapping and during hardening, features a high casting uniformity, and has a refined dendritic structure.

获取价格

Effects of Rare Earths on Microstructure and Wear Resistance in Metal

2024/1/20 Moderate amounts of REEs can improve the hardness and wear resistance of metals, but too much or too little REEs may have negative effects. Compared with micro-REC particles, nano-RECs can obtain a finer and denser microstructure, and the prepared coatings have better hardness and wear resistance. 7. Perspective

获取价格

Low friction and wear resistance in engineering plastics - MCAM

Wear resistance is the ability of a material to resist the progressive loss of volume from its surface through mechanical actions such as repeated rubbing, sliding, or scraping. Wear-resistant materials minimize friction between mating surfaces, allowing parts to retain their form and integrity for longer in applications involving contact between load-bearing surfaces.

获取价格

Comparison of Abrasive Wear Resistance of Hardox Steel and

2024/11/29 The study showed that Hardox Extreme steel exhibits the highest resistance to abrasive wear (value of the coefficient kb is equal to 1.39). In the case of Hadfield steel, the recorded values are slightly lower (kb = 1.32 and 1.33), while the above ratios remain higher compared to Hardox 600 and Hardox 500 steels. ... Metals 2021, 11, 162 ...

获取价格

Wear Resistance of Coated Materials SpringerLink

Govindaraju Madhav Rao, Molian PA (1994) Enhancement of wear and corrosion resistance of metal-matrix composites by laser coatings. J Mater Sci 29: 3274–3280. Article CAS Google Scholar Hornbogen E (1975) Der Einfluss der Bruchzaehigkeit auf den Verschleiss metallischer Werkstoffe (in German).

获取价格Crushing bucket Liuzhou

المحرك الهيدروليكي للكسارات كيف يعمل محرك التروس الهيدروليكي

مطحنة chigayo زيمبابوي

كسارة الحجر 3040

بيع معدات ثقيلة في السعوديه

قيمة كسارة مخروط اندونيسيا

اين سوق ماكنة الخياطه اللبيع في بغداد

قواعد الممارسة للسلامة محطم

الألغام مطحنة صيانة المشرف المحمول

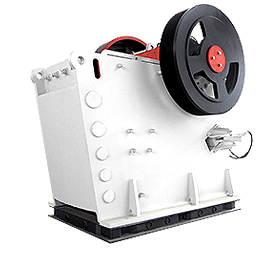

كسارات فكية المعمل للبيع عمان

موردي الرمال الصخرية

تستخدم الكسارات من عمان للبيع

مواصفات مصنع كسارة المحمول في إيران

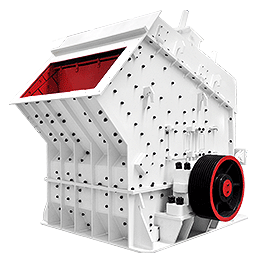

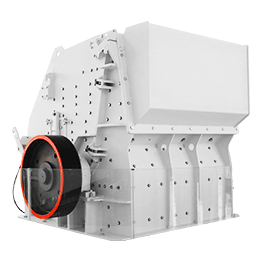

الأمريكية الحجر معدات سحق

لا غربال أسفل كسارة مرحلتين

تهتز أجزاء الشاشة وخطة

الحزام الناقل لصناعة تعدين الفحم

الكسارات الخرسانية باري كولمان بكرات

أسعار خام النحاس الولايات المتحدة الأمريكية

كيف تعمل وخام الحديد محطم

انجلترا طحن آلة مطحنة

من كسارة متنقلة المعدات اللازمة ل

كسارة الرخام للبيع في مصنع تعدين الرخام في النمسا

كم تكلفة مصنع كسارة الصخور

بيع الجزائر كسارة فكية

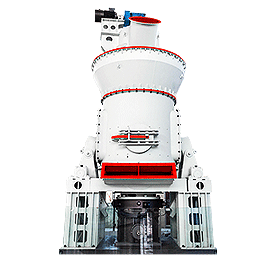

مطحنة طحن فائقة الدقة لمسحوق الجبس

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20