الحار منتجات

ملكنا الإخبارية

Ceramic presintered material crushing

Crushing Pulverizing Grinding Wear Resistant

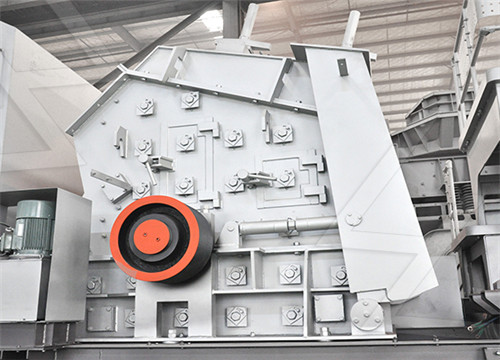

Crushing and pulverizing components designed to reduce the particle size of hard materials will gradually succumb to wear, requiring regular maintenance to ensure optimal performance. Yet most grinding, crushing, and pulverizing

获取价格

RETSCH instruments for ceramic production - McCrone

powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials which are

获取价格

Machining pre-sintered compacts of a sinter-hardenable powder ...

2023/11/3 The machining of pre-sintered ceramic compacts has been investigated in

获取价格

What is Ceramic Sintering? 5 Key Points Explained

Material Transformations During Sintering. Pre-sintered zirconia, for example, transforms from a monoclinic crystalline structure to a polytetragonal state, increasing particle density, strength, and translucency. This transformation

获取价格

RETSCH instruments for ceramic production - ResearchGate

2019/7/10 For fine grinding of hard and brittle sample materials after pre-crushing, ball

获取价格

Titanium Carbide(TiC) Cermet Rod for Wear Resistance

Casting titanium carbide alloy rods in crusher hammers, plate hammers, jaws, concave surfaces, hoods, crushing rollers and other wearing parts, thereby increasing the service life of the equipment and correspondingly saving

获取价格

Revolution of Current Dental Zirconia: A Comprehensive Review

Later, CAD/CAM-based industrial ceramic systems improved machining processes for pre-sintered ceramic blocks to produce infrastructures and prosthetic abutments . Prosthetic restorations containing 3Y-TZP can be fabricated by milling pre-sintered blocks and then sintering them at a high temperature or by fully machining sintered blocks.

获取价格

Machining pre-sintered compacts of a sinter-hardenable powder ...

2023/11/3 The machining of pre-sintered ceramic compacts has been investigated in many studies ... Fig. 4 illustrates the radial crushing strength of the experimental compacts. The considerably lower strength of the compacts pre-sintered at 600 °C and exponential growth above this temperature confirms that the formation of inter-particle necks (i.e ...

获取价格

Oil-based drilling cutting pyrolysis residues- phosphogypsum

2024/10/25 It can be seen from Fig. 7 (a) that, because the raw material of the ODPR is black, all the foamed ceramic pre-sintered blanks prepared are presented with black color, but after the calcined at different temperatures, Fig. 7 (b) shows the appearance of the sintered foamed ceramic products there are some differences in color, with the increase ...

获取价格

A simple way to make pre-stressed ceramics with high strength

2019/12/1 Cylindrical pre-stressed ZrO 2 ceramics were made by the following steps: green body prepared by gel injection molding → binder removal → pre-sintering → sol-gel dip alumina coating → drying → sintering. The gel injection materials are composed of acrylamide premix solution (210 g/batch), acrylic/methacrylic acid salts dispersant (21 g/batch), organic

获取价格

Development of an electric arc furnace steel slag-based ceramic ...

2022/7/1 Development of an electric arc furnace steel slag-based ceramic material for high temperature thermal energy storage applications. ... Slag thermal pre-treatment, shaping pressure, firing temperature, duration, and atmosphere were studied. ... we obtained a slag-based sintered material with a 3080 kg/m 3 density, a specific heat of 1 kJ/(kgK ...

获取价格

Advances in Texturing and Thermoelectric Properties of a Calcium ...

2024/10/23 Employing PS with the same pre-sintering temperatures (973–1193 K) as those used by Noudem et al. [13, 53, 54, 57] resulted in the crushing of the pre-sintered pellets during SPT, which has not been addressed before. Considering the brittleness of this material, it seems unlikely that the pellets used will remain without breakage during SPT ...

获取价格

Cold sintering: An innovation in ceramic manufacturing

2024/10/1 Cold sintering is a method for densifying ceramic materials at temperatures less than 400°C. ... As stated above, cold sintering densifies ceramic materials at relatively low temperatures compared to hot sintering, and in much less time as well (as fast as 15 minutes). It achieves this feat by using a liquid phase and external pressure to ...

获取价格

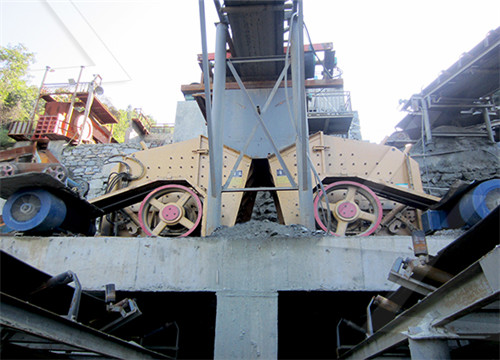

Optimization of roller teeth based on the analysis of the

the diversity of sintering raw materials and the complexity of crushing particle size, people have not been able to make a perfect explanation of the crushing mechanism between sintered ore and crushing equipment. The particle size composition of crushing products is an important factor to determine the crushing effect of mineral processing

获取价格

SG Silicon Carbide SG SiC Material Supplier

Machining in the pre-sintered, or green, state is desirable because it allows manufacturing of complex finished shapes without expensive grinding of sintered material. Green machining is accomplished using conventional processes. Stock removal can be accomplished 15 times faster in the green state than in the sintered state.

获取价格

Hexoloy SiC Alpha Silicon Carbide Material - Saint-Gobain

The Hexoloy ® SiC material was developed in late 1970s. Since that time, Saint-Gobain Performance Ceramics Refractories’ engineers have successfully commercialized Hexoloy ® in a wide range of industrial applications. The unique properties of Hexoloy ® SiC allow it to outperform commonly used ceramic materials in harsh operating conditions. Saint-Gobain

获取价格

Preparation of low-shrinkage and high-performance

2019/6/15 As-prepared products have uniform microstructure and excellent mechanical properties. The influence of the pre-sintering temperature and addition amount of the pre-sintered powder on the viscosity of alumina suspension as well as flexural strength, linear shrinkage and relative density of alumina sintered body was also investigated.

获取价格

The Zirconia Ceramic: Strengths and Weaknesses - PMC

Ceramic material used, core-veneered bond-strength, and crown thickness are some factors essential to withstand occlusal forces . ... , direct ceramic soft- machining of pre-sintered 3Y-TZP is now on the market. First, the die or the wax pattern is scanned, the computer software (CAD) designs an enlarged restoration and computer aided machining ...

获取价格

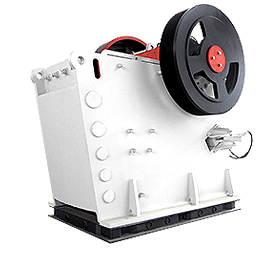

Mechanical Activation as Sintering Pre-treatment of Talc for

Mechanical Activation as Sintering Pre-treatment of Talc for ... design of ceramic materials [13, 14]. The activation of a solid substance is accomplished by ... talc sample was conducted by jaw crusher, with 10 mm output opening, working in a closed circle with screen. Afterwards, primary crushed sample was subjected to crushing in the roll

获取价格

Hexoloy SiC Alpha Silicon Carbide Material - Saint-Gobain

The Hexoloy ® SiC material was developed in late 1970s. Since that time, Saint-Gobain Performance Ceramics Refractories’ engineers have successfully commercialized Hexoloy ® in a wide range of industrial applications. The unique properties of Hexoloy ® SiC allow it to outperform commonly used ceramic materials in harsh operating conditions. Saint-Gobain

获取价格

Preparation of low-shrinkage and high-performance

2019/6/15 As-prepared products have uniform microstructure and excellent mechanical properties. The influence of the pre-sintering temperature and addition amount of the pre-sintered powder on the viscosity of alumina suspension as well as flexural strength, linear shrinkage and relative density of alumina sintered body was also investigated.

获取价格

The Zirconia Ceramic: Strengths and Weaknesses - PMC

Ceramic material used, core-veneered bond-strength, and crown thickness are some factors essential to withstand occlusal forces . ... , direct ceramic soft- machining of pre-sintered 3Y-TZP is now on the market. First, the die or the wax pattern is scanned, the computer software (CAD) designs an enlarged restoration and computer aided machining ...

获取价格

Mechanical Activation as Sintering Pre-treatment of Talc for

Mechanical Activation as Sintering Pre-treatment of Talc for ... design of ceramic materials [13, 14]. The activation of a solid substance is accomplished by ... talc sample was conducted by jaw crusher, with 10 mm output opening, working in a closed circle with screen. Afterwards, primary crushed sample was subjected to crushing in the roll

获取价格

SA Sintered Silicon Carbide SA SiC Material Supplier

Hexoloy ® SA SiC is a pressure-less, sintered form of alpha silicon carbide, with a density greater than 98% theoretical. It has a very fine grain structure (4-10 microns) and contains no free silicon. Hexoloy ® SA SiC‘s chemical purity and engineered microstructure ensures excellent resistance to a wide range of chemicals. It is also highly resistant to wear from rotation and sliding ...

获取价格

(PDF) Preparation and characterization of sintered clay ceramic ...

2019/12/13 EDS spectrum of C900-50-15-35 used sintered ceramic filter. ... materials were taken in the required proportion, mix ed for. ... macroporous ceramics from pre-ceramic precursors.

获取价格

Properties of Porous Mullite Filter Material Fabricated from

and 10 MPa before being sintered at 1600 C for 3 h. 2.1.3 Mullite Filter. Pre-reacted mullite (with 3 wt.% PEG 400) and mullite mix granules were mixed with ammo-nium hydrogen carbonate (40 vol.%), pressed at 20 and 30 MPa for 30 min and sintered at temperatures from 1700 to 1800 C in the muffle furnace. To avoid crushing, the pre-

获取价格

Micro machining of pre-sintered ceramic green body

2012/3/1 Most of ceramic materials can be used as abrasive particles in grinding or polishing. Although the pre-sintered ceramic matrix is softer than the sintered ceramic and the material can be easily removed, the ceramic particle is

获取价格

MSE 160 – Ceramic synthesis and characterization

Sintering References Ceramic Materials Science and Engineering by C.B. Carter M.G. Norton Springer Powder processing 25 26. EngrMSE 160, 2020 Winter 2/4/2020 Research activities Synthesis of nanoscale oxide materials Co-precipitation of rare

获取价格

Fabrication Technologies of the Sintered Materials Including Materials ...

2017/3/29 This chapter of the book presents the basis of classical powder metallurgy technologies and discusses powder fabrication, preparation, preliminary moulding, sintering and finish treatment operations. A general description of the materials and products manufactured with the classical powder metallurgy methods is presented. New variants are characterised along

获取价格

Waste-derived glass-ceramic LTCC materials prepared from

2023/12/1 Of these glass-ceramic materials, CaO-MgO-SiO 2 glass-ceramics are extensively employed in the electronic packaging industry as a type of low-temperature co-fired ceramic (LTCC) material [12] because of their low dielectric constant and loss. LTCC is a technology in which circuit are prepared by ceramic co-fired with metal wiring at low ...

获取价格

In-situ SEM cyclic nanoindentation of pre-sintered and sintered ...

2022/2/1 Efficient diamond machining of zirconia requires a comprehensive understanding of repetitive diamond indentation mechanics. This paper reports on in-situ cyclic nanoindentations of pre-sintered and sintered zirconia materials performed inside a scanning electron microscope (SEM).In-situ SEM imaging of cyclic indentation processes and high-magnification SEM

获取价格

Ch 16 CERAMICS Flashcards - Quizlet

Study with Quizlet and memorize flashcards containing terms like Chapter 17. What is the difference between the traditional ceramics and the new ceramics, as far as raw materials are concerned?, List the basic steps in the traditional ceramics processing sequence, What is the technical difference between crushing and grinding in the preparation of traditional ceramic

获取价格

Ceramics Processing - an overview ScienceDirect Topics

Ceramic biomaterials for tissue engineering. Jie Huang, Serena M. Best, in Tissue Engineering Using Ceramics and Polymers (Third Edition), 2022. 1.6 Processing of ceramics. The objective of ceramic processing is to make a specific form of the material that will perform a specific function, such as space-filling, tissue bonding or replacement.

获取价格ميسين سيدوت باسير ميريك كهايا ماس إد

سعر محطة التكسير المتنقلة للصخر الزيتي

هيدروليكي نظام هس سحق

مواصفات 106 كسارة

B مخروط محطم قطع الغيار لل

عيوب لإعادة تدوير الحديد

الحجر الجيري طحن حفر

sbm LT1110 كسارة الجانب الناقل

منجم الفحم أوستار منجم الفحم أوستار 兖州煤业股份有限公؟

معدات ثقيلة للشراء تركتر مزاج الحراج

نوع من الكسارات المستخدمة لسحق خام النحاس

أرخميدس أفضل نوع كسارة تحت الأرض

قائمة معظم آلات التعدين مكلفة

مرحلة انزلاق الخيالة التكلفة الإجمالية آلات مصنع سحق

دليل المشتري الحجر الجيري المعدنية بنغلاديش

البورصة غرامة حجر محطم

آسیاب توپ دانلود تصویر

صور ادوات البناء الكبيرة والواضحة

طحن مطحنة للتعدين كندا

شريك في مشروع مشترك مع عملية التعقب الذهب والفضة

آلة تكسير الحجر الجيري الصين

تستخدم الحجر الجيري مزود تأثير محطم المملكة العربية السعودية

التعدين حديقة التقطيع

تاجر معدات بناء في السعودية

خط إنتاج لوحة الجدار ساندويتش اسمنت

آلات الحجر في إيطاليا

حول لدينا

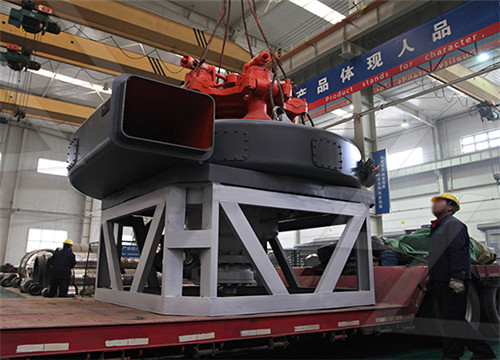

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20