الحار منتجات

ملكنا الإخبارية

over view of ball mill cement plant

EVERY COMPONENT OF BALL MILL DETAILED

Fine Grinding and Mill Cooling. PROBLEM. Insufficient mill cooling lead to material agglomeration on balls and liners. The grinding is not any more done by balls against material but by material against material. SOLUTION. Adapted

获取价格

Vertical roller mill vs. ball mill for cement grinding: Comparison the ...

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends

获取价格

Vertical roller mill vs. ball mill for cement grinding: Comparison

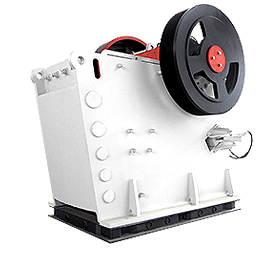

Overview of Ball Mill. A ball mill is a traditional grinding machine that has been used in the cement industry for decades. It consists of a rotating cylinder filled with steel balls that crush and grind the material as the cylinder rotates. Ball mills are known for their reliability and ability to grind materials to a fine consistency.

获取价格

EVERY COMPONENT OF BALL MILL DETAILED

Fine Grinding and Mill Cooling. PROBLEM. Insufficient mill cooling lead to material agglomeration on balls and liners. The grinding is not any more done by balls against material but by material against material. SOLUTION. Adapted

获取价格

Ball Mill Liner: What is it and How it Works? - AGICO

Ball mill liners are essential components in the operation of a ball mill. They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan

获取价格

Enhanced grinding process of a cement ball mill through a

1 For a cement ball mill grinding process 11, Several intelligent controllers designed based on fuzzy logic 10,11 for the cement ball mill grinding process were able to track the setpoint and reject ...

获取价格

Ball Mill In Cement Plant - Selling Various Types Of Cement Mill

Ball mills in cement plants have a wide range of applications, including: Grinding of raw materials: The primary function of a ball mill in a cement plant is to grind the raw materials used in the production of cement. These raw materials typically include limestone, clay, iron ore, and sometimes sand.

获取价格

Ball Mill For Cement Grinding – Cement Ball Mill Ball Mill

Cement Ball Mill AGICO Adopt Efficient Cement Separator. The function of cement separator is to reduce the unnecessary grinding amount of cement ball mill and improve its grinding efficiency by screening out the particles with certain fineness in time. The key technologies of cement separators are dispersion, classification, and collection.

获取价格

The Comprehensive Guide to Cement Plant Costs: An In-Depth

6. Cement Mill. The cement mill grinds the clinker to a fine powder, which is then mixed with gypsum to form cement. Equipment: Ball mills, vertical roller mills. Technical Specifications: Ball Mills: 10-30 tons/hour capacity, 500-1500 kW motor power. Vertical Roller Mills: 20-50 tons/hour capacity, 1000-3000 kW motor power. Example Brands:

获取价格

Cement ball mill process calculation pdf PPT - SlideShare

2024/1/5 Closed-circuit ball mill grinding plant Advantage: Lower power consumption than an open circuit ball mill High cement fineness achievable Cement fineness can be controlled with separator adjustment Disadvantage: Closed-circuit mills are more sophisticated and can have more technical problems Larger space requirement Higher investment cost (+ 25 ...

获取价格

Ball Mill Pinion Gear - cement grinding plant s

Application: Cement plant. Certificates: ISO9001:2015. Free Inquiry. Product Introduction. The girth gear and pinion are transmission devices of ball mills. They are toothed mechanical parts that can mesh with each other. When the ball mill rotates, the pinion on the reducer meshes with the girth gear, thereby driving the ball mill to run ...

获取价格

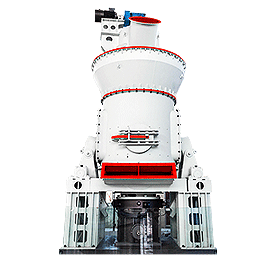

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.. The VRM cement mill has a

获取价格

Design and Optimization of Ball Mill for Clinker Grinding in

For commercial cement plant ball mill 12 m long, 3.8 m diameter, calculations performed using design equations showed top side steel ball size M = 127 mm; mill speed actual n = 16.6 rpm; grindability G = 1.69 g/rev, for throughput 80 T/hr clinker grinding from ~ 40 mm size down to average 5–6 microns,

获取价格

Cement Grinding Plant Overview Cement Grinding Unit - Cement Plant

Cement grinding machine selection will directly decide the quality and cost of whole cement grinding unknit. According to the real cement projects, there are three common solutions for cement grinding plant. Cement roller press and ball mill; Closed-circuit cement mill; Cement crusher and ball mill; In summary, the first solution will be the ...

获取价格

Cement Ball Mill Cost Effective Cement Grinding ... - AGICO Cement Plant

The installation of liners. Length Diameter Ratio. The length-diameter ratio of the cement ball mill is relatively large. For mills of open-circuit grinding system, the length-diameter ratio is usually between 3.5 and 6 to ensure that the product fineness is qualified through single grinding; For ball mills in closed-circuit grind system, in order to increase the material flow rate, the length ...

获取价格

What Are the Parts of a Cement Mills? - Cement Ball Mill

2023/8/23 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder. This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement. To achieve this crucial transformation, a cement mill comprises

获取价格

Design and Optimization of Ball Mill for Clinker Grinding in

For commercial cement plant ball mill 12 m long, 3.8 m diameter, calculations performed using design equations showed top side steel ball size M = 127 mm; mill speed actual n = 16.6 rpm; grindability G = 1.69 g/rev, for throughput 80 T/hr clinker grinding from ~ 40 mm size down to average 5–6 microns,

获取价格

Cement Grinding Plant Overview Cement Grinding

Cement grinding machine selection will directly decide the quality and cost of whole cement grinding unknit. According to the real cement projects, there are three common solutions for cement grinding plant. Cement roller press and

获取价格

Cement Ball Mill Cost Effective Cement Grinding

The installation of liners. Length Diameter Ratio. The length-diameter ratio of the cement ball mill is relatively large. For mills of open-circuit grinding system, the length-diameter ratio is usually between 3.5 and 6 to ensure that the product

获取价格

What Are the Parts of a Cement Mills? - Cement Ball Mill

2023/8/23 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder. This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement. To achieve this crucial transformation, a cement mill comprises

获取价格

Vertical Cement Mill, Vertical Roller Mill Buy Cement ... - Cement Plant

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind

获取价格

Ball Mill Diaphragm - Cement Plant

Cement ball mill diaphragm. Material:High manganese steel, high chromium cast iron or rubber. Standards:standard or customized by drawings. ... AGICO CEMENT supplies EPC projects for both cement plant and single cement plant equipment. CONTACT INFO +86 13683722138. info@cement-plants. 19F, Suite B, Global Trade Mansion, Wenfeng Avenue ...

获取价格

Grinding in Cement Manufacturing: Key Process, Types of Mills,

Types of Mills Used in Grinding 1. Ball Mills. Ball mills are one of the most commonly used types of equipment for cement grinding. They utilize steel balls as grinding media to crush and grind the raw materials into fine powder. The process operates in a continuous cycle: Material Feeding: The raw materials are fed into the mill.

获取价格

a) Cement ball mill view, b) Cement mill sketch.

Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement. The research focuses on the mill speed as well as air classifier speed effect on the two ...

获取价格

Cement Ball Mill Ball Mill For Sale Cement Mill - Cement Plant

The ball mill price is affected by the following factors, you can choose a suitable cement ball mill according to these factors. Cost of production: materials cost, human cost, electricity power cost, etc.; Technical costs: technology import, equipment optimization, and upgrading.; Capacity: more large-scale, more complete service, and more cost-effective.

获取价格

BALL MILL - Cement

FLS Cement flsmidth-cement 3 Ball mill for cement grinding Cement grinding is a crucial stage of the flow sheet, where both cement quality and process efficiency are decided. Achieving the required fineness with maximum efficiency is down to the design of the ball mill and how well it runs. An inefficient system

获取价格

Energy and exergy analyses for a cement ball mill of a new

2020/2/1 Nowadays, ball mills are used widely in cement plants to grind clinker and gypsum to produce cement. In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and ...

获取价格

Cement mill - Wikipedia

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

获取价格

3 Necessary Cement Milling Comparison Ball Mill ... - Cement Plant

2020/11/5 As you all know, the process of a cement manufacturing plant can be divided into several steps, including crushing, raw milling, clinker calcining, cement milling (or cement grinding), packing and etc. In the complete cement production line, the cement mill process plays a very important role. The design of cement milling and cement mill process will produce a

获取价格

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL

handled by the plant’s maintenance crew. Upgrading the classifier and baghouse involves capital expenditure with a high benefit to cost ratio. Optimization is especially important when multiple products are being produced. Operation and Elements of a Closed-Circuit Ball Mill System . Cement ball mills typically have two grinding chambers.

获取价格إعادة تدوير الصخور النهرية تكسير الأمبيرات

آلة لفة الكسارات لفة مزدوجة مسننة

تركيب من كسارة الصخور

نوع الشركات المصنعة لمعدات معالجة المعادن

محطم المجاميع ألمانيا

محطم من الصين Sangai أنواع

التعاقد مع مشغل كسارة في أستراليا

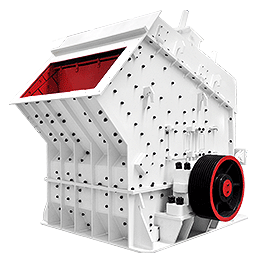

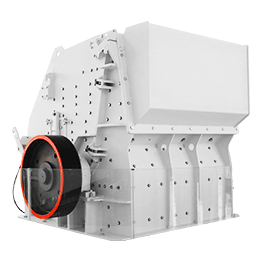

كسارة الحجر تأثير كسارة كسارة صناعية للبيع

تهتز الشاشة المصنعين الهند تهتز الصناعي

أتمتة مطحنة الأسطوانة باستخدام سكادا

عميقة الفحم معدات التعدين

بوفيه نادي بطولات الدوري كسارات

آلة التوازن الرأسي التلقائي بالكامل مع تصحيح طحن

محطة كسارة الحجر لسعر البيع في الهند

تهتز آلة الشاشة التكلفة

كيف تخطيط العملية المتعلقة بصناعة الأسمنت كسارة الصخور

خط إنتاج مطحنة سلسلة qbm الموفرة للطاقة

سعر آلة كسارة الحجر المتنقلة في ماليزيا

كسارة المطرقة شركة

سعر كسارات الرمل سعر البيع في المكسيك

شركة إنتاج شنغهاي

مخطط تدفق التكسير والغربلة المنقولة جنسياً

الولايات المتحدة الأمريكية كسارة الجبس

ساخت مناطق برای زیرکون سنگ زنی

تأثير محطة كسارة متنقلة من baichy

اجمل اغاني عبد العزيز كسار

حول لدينا

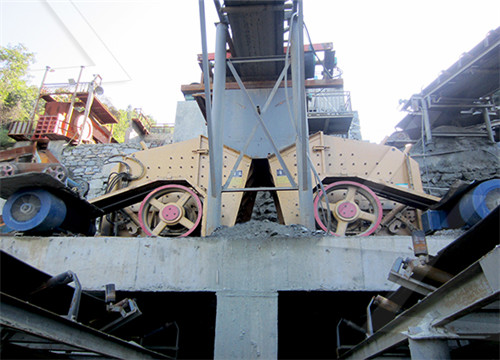

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20