الحار منتجات

ملكنا الإخبارية

iron ore crushing system

Crushing Plant Design and Layout Considerations - 911

crusher’s discharge opening, as the production continues through an on-line coarse size

获取价格

Comminution and classification technologies of iron ore

2022/1/1 Some examples of different iron ore crushing and screening flowsheets are

获取价格

Crushing Plant Design and Layout Considerations - 911

crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climatic

获取价格

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening ... a smooth crushing process and minimise downtime in the event of a breakdown or to allow planned

获取价格

Iron Ore Pellets Crushing Test System - Precision Robotics

Determination of Cold Crushing Strength (CCS) of iron Ore pellet fired at different temperature. This machine is mainly used in crushing strength test for iron ore pellet, with functions of automatically statistical analysis of iron ore pellets test result as average crushing strength, CV% standard deviation (SD) and calculate CCS force..

获取价格

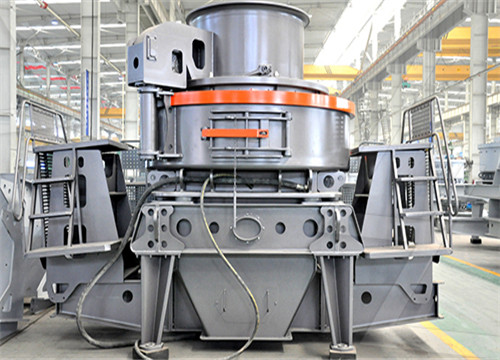

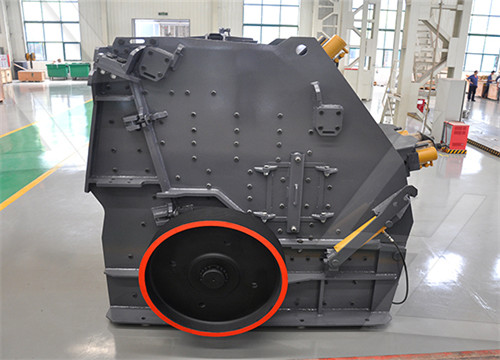

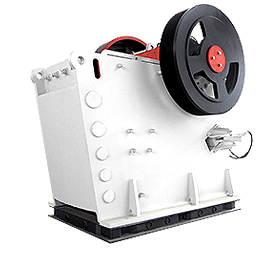

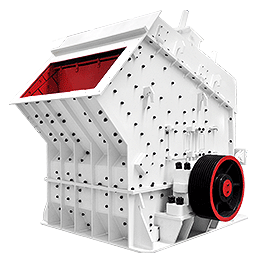

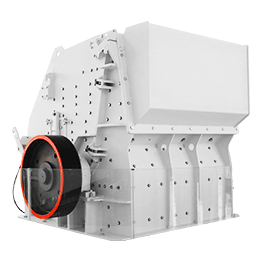

The 4 Types Iron Ore Crushing Stations You Must Know

2023/3/31 Iron ore crushing station generally consists of four parts of equipment: feeding equipment, crushing equipment, buffer silo, and unloading equipment. ... adjustment, and locking functions are all realized by hydraulic devices, the hydraulic system can effectively ensure the safe operation of the equipment. On the one hand, the equipment is wear ...

获取价格

Intelligent dry fog dust suppression system: an efficient

2020/11/21 The system has been implemented in an iron ore crushing and screening plant in India, and its efficacy has been evaluated for controlling dust emission. The installed dry fog system reduced dust concentration to 0.10–0.17 mg m−3 from the prevailing dust concentration of 0.62–1.73 mg m−3 in work zone areas, which was much below the ...

获取价格

Simheuristic-based decision support system for efficiency

2020/9/1 The processed ore size defines the type and position of each stage. For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m. In the quaternary crushing stage, the size of the ore that feeds the crushers is less than 20 mm. Screens classify the ore by size and ...

获取价格

Simheuristic-based decision support system for efficiency improvement ...

2020/9/1 The processed ore size defines the type and position of each stage. For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m. In the quaternary crushing stage, the size of the ore that feeds the crushers is less than 20 mm. Screens classify the ore by size and ...

获取价格

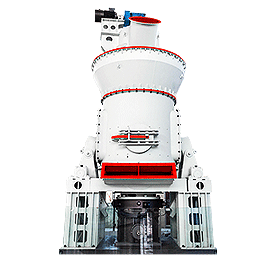

Research into the crushing and grinding processes of iron

Technological cycle of iron ore crushing and grinding under production conditions is possible only in terms of mechanical load being rather labour-consuming and energy- ... Equation (1) is represented by the following system of three scalar equations for each coordinate axis: 2

获取价格

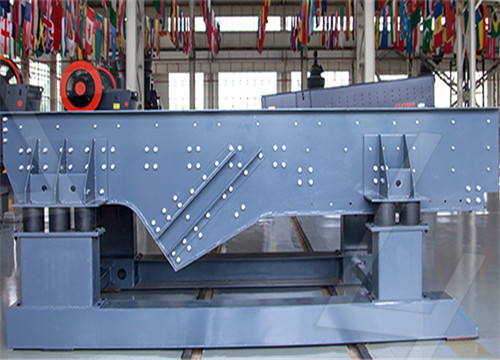

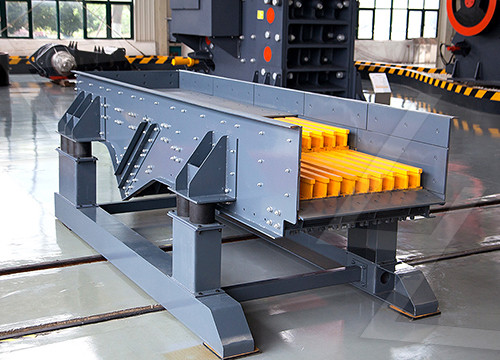

Advances in screening technology in the mining sector

The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. While good quality magnetite is now dry-processed, hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminations. The fineness requirements depend on ...

获取价格

A Mine-to-Crusher Model to Minimize Costs at a Truckless Open-Pit Iron ...

2022/8/18 A truckless mining system or in-pit crushing and conveying system is a sustainable and cost-efficient alternative compared to hauling by trucks, considering long hauls and non-selective mining and dumping. ... Although this study was based on an iron-ore mine with specific characteristics, the mine-to-crusher model could be applied in other ...

获取价格

Iron Ore production in the Pilbara - Rio Tinto

Iron Ore production in the Pilbara Rail and port operations Rail Ore is railed up to 460 kilometres to the coast along a dedicated privately owned rail system. A typical train consist comprises 2 GE Dash 9 locomotives, 230 ore cars and is over 2.4 kilometres long. A single driver, supported by centralised track control, operates the train.

获取价格

Instruments for Physical Testing of Iron Ore

of Iron Ore Pellet Crushing Strength Determinator - RB 1000 The RB 1000 Iron Ore Pellet Crushing Strength Determinator is an automated system for the determination of the crushing strength of fired iron ore pellets and reduced iron ore pellets, according to ISO 4700 Standard and ASTM E 382-83 Standard.

获取价格

Measurement-Control for Crushing and Screening Process

2023/6/3 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control. Crushing Process Control. To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for

获取价格

Can in-pit crushing and conveying make mining more sustainable?

2022/5/17 “In one study, an IPCC system replaced an overburden truck fleet that moved material from the mine face to the top of the in-pit dump. This reduced haulage energy by 63 percent. And if the system is powered by renewables, it could replace 3.5 Olympic swimming pools of diesel per year for each shovel swapped over.” IPCC system at Vale's S11D ...

获取价格

Iron Ore production in the Pilbara - Rio Tinto

Iron Ore production in the Pilbara Rail and port operations Rail Ore is railed up to 460 kilometres to the coast along a dedicated privately owned rail system. A typical train consist comprises 2 GE Dash 9 locomotives, 230 ore cars and is over 2.4 kilometres long. A single driver, supported by centralised track control, operates the train.

获取价格

Instruments for Physical Testing of Iron Ore

of Iron Ore Pellet Crushing Strength Determinator - RB 1000 The RB 1000 Iron Ore Pellet Crushing Strength Determinator is an automated system for the determination of the crushing strength of fired iron ore pellets and reduced iron ore pellets, according to ISO 4700 Standard and ASTM E 382-83 Standard.

获取价格

Measurement-Control for Crushing and Screening Process

2023/6/3 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control. Crushing Process Control. To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for

获取价格

Can in-pit crushing and conveying make mining more sustainable?

2022/5/17 “In one study, an IPCC system replaced an overburden truck fleet that moved material from the mine face to the top of the in-pit dump. This reduced haulage energy by 63 percent. And if the system is powered by renewables, it could replace 3.5 Olympic swimming pools of diesel per year for each shovel swapped over.” IPCC system at Vale's S11D ...

获取价格

Pellet CCS (Cold Crushing Strength) Testing Machine

Pellet CCS (Cold Crushing Strength) Testing Machine Insmart make state of art technology Cold Compressive Strength (CCS) testing machine is designed and developed in accordance with IS 8625-1986, ISO 4700 and ASTM E 382 standards. ... The standard machine is for fired iron ore pellets. Highlights; Designed and developed in accordance with IS ...

获取价格

In Pit Crushing Conveying (IPCC) and material handling system

An overall layout of the system at Simandou in Guinea (f.r.t.l.): Two primary In Pit Crushing Conveying (IPCC) systems incorporating TAKRAF X-TREME class sizers, a secondary In Pit Secondary Crushing Conveying (IPSCC) system also incorporating TAKRAF sizers, a stockyard with two stackers and two reclaimers, a complex conveyor system with transfer stations linking

获取价格

In Pit Crushing Conveying (IPCC) and material handling system ...

2023/11/7 The Simandou iron ore project is one of the largest unexploited high-grade iron ore deposits in the world. With the project’s development reaching an important milestone in March this year, the project’s partners have been able to kick off with development work, including support from the government of Guinea with defined requirements for the start of production.

获取价格

Beneficiation of Iron Ores - IspatGuru

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc., but the advantage is only partial removal of adhered alumina and free

获取价格

Crushing Plant - an overview ScienceDirect Topics

Developments in iron ore comminution and classification technologies. A. Jankovic, in Iron Ore, 2015. 8.2.4 Mobile crushing and screening plant applications for small- to medium-sized iron ore projects. There is now a new generation of mobile crushing and screening plant systems, which have been developed based on the motivation of reducing ...

获取价格

Mineral Sizers - McLanahan

Mineral Sizers are used to process high volumes of hard rock minerals such as iron ore, copper, gold and nickel in primary crushing applications, as well as soft, non-coal minerals, lower capacity battery minerals and rare earth minerals such as spodumene, antimony and

获取价格

TRUSTON Intelligent Crusher

Iron ore crushing and screening system. Iron ore crushing plant is a stepped crushing process: crushing block raw material from about 500mm to fine material about 0-10mm, using primary. 400 tph sand-making production line in Chongqing. Sand is widely used in road construction, real estate development, concrete making etc. With the rapid ...

获取价格

RB Automazione - RB 1000 CCS Equipment for iron ore pellets

General description. According to ISO 4700, ASTM E 382 and IS 8625 Standards, RB 1000 is a fully automatic system for determination of the crushing strength of fired iron ore pellets and reduced iron ore pellets, by measuring continuously sample dimensions and crushing load. The equipment consists of a loading unit, with an automatic handler and feeder for the samples

获取价格

Beneficiation of Iron Ore - 911Metallurgist

2016/5/24 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring

获取价格كسارة الذهب nstone nfor nsale

سعر كسارة pembekal

غسل الرمل و طحن

رمل ابيض

كسارة harga mesin 20

مبادئ إنتاج ثاني أكسيد التيتانيوم

کارخانه شن و ماسه در شرکت های شیشه ای

كسارات عالية الكفاءة تأثير كسارة أثر ثقيل من الصين

توفير الطاقة مطحنة الكرة flyash من الصين أفضل منتج

شنت جرار آلات تكسير الحجر

أفضل نوعية تهتز شاشة الخصم تهتز الشاشة

الكسارات المحمولة المستخدمة للبيع الولايات المتحدة الأمريكية

الآلات محطم مصنعين

تاريخ صناعة معدات تكسير الحجارة في الهند

نوع مصنع كسارات الحجر

مستورد كسارة خام

قطرها العروس

سيارات المانية معدات ثقيله

قائمة شركة محجر 3 4 الحصى

المصنعين إيطاليا كسارة الحجر

الخليط ادلي الخليط

1000 ذروة مخروط محطم

الشركات الصينية إنتاج الكسارة المحورية

مستعملة الموردون الذهب خام محطم في

أين يمكنني شراء آلة لصنع الباستيل

كسارة خام الحديد المحمولة مزود جنوب أفريقيا

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20