الحار منتجات

ملكنا الإخبارية

process in mining iron ore

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction. The most common method of ironmaking is the blast furnace route. In a blast

获取价格

Iron ore - Wikipedia

Metallic iron is virtually unknown on the Earth's surface except as iron-nickel alloys from meteorites and very rare forms of deep mantle xenoliths. Although iron is the fourth-most abundant element in the Earth's crust, composing about 5%, the vast majority is bound in silicate or, more rarely, carbonate minerals, and smelting pure iron from these minerals would require a prohibitive amount of e

获取价格

Iron Mining Process

Iron Mining Process. From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel. Blasting Taconite is a very hard rock. Using explosives, the

获取价格

Iron Ore production in the Pilbara - Rio Tinto

Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control are fundamental to the process.

获取价格

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS

获取价格

Iron Ore Mining Process: From Extraction to Export

2023/12/19 Using a process that combines coking coal with reduced iron pellets, steelmaking has become one of the world's most vital industries. In the 1800s, ... Everything in iron ore mining is big. Australia possesses one of the longest private rail networks in the world, designed solely for transporting mile-long ore trains to port facilities. ...

获取价格

Iron Ore Processing: From Extraction to Manufacturing - Mining

2024/4/26 The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction. The most common method of ironmaking is the blast furnace route. In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the top.

获取价格

Iron Ore Mining – The process of iron ore mining - Atlam Group

The Process of Iron Ore Mining. Mining iron ore is a physically and chemically demanding process that takes place in remote locations around the world. The process begins with exploration, which can be done through surface or underground methods. Once a deposit is

获取价格

Energy and Environmental Profile of the U.S. Mining

4.1 Process Overview 4.1.1 Iron Ore Mining There are two basic methods of mining iron ore. These are: • Surface mining or open-pit mining • Underground or shaft mining To be competitive, iron mining must be done on a very large scale. Surface mining is the preferred choice, although there are exceptions.

获取价格

Iron processing - Ores, Smelting, Refining Britannica

Iron processing - Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of

获取价格

Iron Ore - Geoscience Australia

2023/12/19 Marillana: In May 2018, Brockman Mining Ltd upgraded the Marillana Iron Ore Project's JORC (2004) Mineral Resource estimate, published in 2010, to comply with JORC (2012). Brockman stated that the upgraded, ... 4 Agglomeration is the process in which magnetite grains are aggregated into pellets using a chemical binding reagent. Pellets are ...

获取价格

Iron Ore Processing, General - SpringerLink

2022/10/20 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills. Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions. It is the link between the mined raw materials ...

获取价格

Top 6 Steps Of Iron Ore Processing - Australian Mining Services

2023/9/18 Alternatively, call us on 1300 241 620 to speak to our experts today and learn all about the mining iron ore process. Types Of Iron Ore In Australia. Australia is a country that boasts a rich amount of iron ore, and several types are extracted and processed to meet both domestic and international demands. Let’s discuss the primary types:

获取价格

Iron Ore Processing, General - Springer

iron ore mining because they are either labor-intensive or costly. ... to as room and pillar mining. Retreat mining is a process that recovers the support-ing coal pillars, working from the back of the mine toward the entrance, hence the word retreat. Room and pillar mining advance inward, away from the entrance of

获取价格

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

2015/4/3 The process of mining of iron ore from discovery of an iron ore deposit body through extraction of iron ores and finally to returning the land to its natural state consists of several distinct steps. The first is discovery of the iron ore deposit, which is carried out through prospecting or exploration to find and then define the extent ...

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore. More than 85% of the hematite ore reserves are of medium- to high-grade (+62% Fe) and are directly used in blast furnace and in direct-reduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and agglomerated pellets (Iron and

获取价格

Top 6 Steps Of Iron Ore Processing - Australian

2023/9/18 Alternatively, call us on 1300 241 620 to speak to our experts today and learn all about the mining iron ore process. Types Of Iron Ore In Australia. Australia is a country that boasts a rich amount of iron ore, and

获取价格

Iron Ore Processing, General - Springer

iron ore mining because they are either labor-intensive or costly. ... to as room and pillar mining. Retreat mining is a process that recovers the support-ing coal pillars, working from the back of the mine toward the entrance, hence the word retreat. Room and pillar mining advance inward, away from the entrance of

获取价格

Understanding Iron Ores and Mining of Iron Ore –

2015/4/3 The process of mining of iron ore from discovery of an iron ore deposit body through extraction of iron ores and finally to returning the land to its natural state consists of several distinct steps. The first is discovery of the iron

获取价格

Iron ore beneficiation: an overview - ScienceDirect

2023/1/1 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore. More than 85% of the hematite ore reserves are of medium- to high-grade (+62% Fe) and are directly used in blast furnace and in direct-reduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and agglomerated pellets (Iron and

获取价格

Iron Ore Benification process Presentation.pptx - SlideShare

2024/7/30 Production amount of iron ore in Sishen mine Sishen Mine is one of the largest iron ore mines in South Africa. producing millions of tons of iron ore concentrate annually. Ore reserves were estimated to be 519.4Mt, including 507.1Mt from open-pit and 12.2Mt from run-of-mine buffer stockpiles, in 2019. The mine produced 29.2Mt in 2019.

获取价格

Iron Ore: From Mining to Processing to Dust Control

As of 2020, the largest global iron ore—producing companies were: Vale (Brazil, 300 million tons). The largest exporter of iron ore and the Americas’ largest mining company with a reserve of nearly four billion tons, Vale produces 80% of Brazil’s iron ore. Rio Tinto (United Kingdom Australia, 286 million tons).

获取价格

Iron Ore Mining Techniques Metal Extraction - GREAT MINING

The smelting process involves heating the iron ore with carbon. Carbon combines with the oxygen and removes it, leaving behind iron. Blast furnaces reach extremely high temperatures, which melt the iron, allowing it to be drained off and poured into molds to form bars known as ingots. ... MINING AND PROCESSING: Iron ore mining can be broadly ...

获取价格

Our Mining Process - Iron Ore Company of Canada

IOC pellets are high quality with a clean chemistry, which helps to lower the carbon footprint compared to lower quality grades and forms of iron ore when used in the iron steel industry.","3835":"At IOC we are committed to becoming a premier mining organization in

获取价格

Iron (Fe) Ore Minerals, Occurrence » Geology Science

2023/5/7 Iron ore deposits Mining and Processing. Mining and processing of iron ore involve several stages, including exploration, development, extraction, beneficiation, and transportation. The overall process can vary depending on the type of iron ore deposit, its location, and the economics of extraction.

获取价格

How is Iron Produced – Full Guide to Iron Mining and Production

2024/6/11 The mining of iron ore and the smelting process in blast furnaces contribute to air pollution and greenhouse gas emissions. The use of coke as a reducing agent releases a substantial amount of CO2, while the mining operations can lead to deforestation, soil erosion, and habitat destruction. Moreover, the slag and other waste materials, if not ...

获取价格

Iron Ore Processing - an overview ScienceDirect Topics

Resource Recovery and Recycling from Metallurgical Wastes. S. Ramachandra Rao, in Waste Management Series, 2006 9.8 Production of Ceramic Tiles from Iron Ore Tailings. Current practice of washing iron ore before it is processed for extractive metallurgical operation results in three products, coarse ore lumps with sizes in the range 10-80 mm, which are directly charged

获取价格

Environmental impact of iron ore mining - Wikipedia

Hematite-rich iron ore. Iron ore is a mixture of rocks and minerals containing enough iron content and sufficient volume and accessibility for mining and transportation to be economically mined. [5] Around five percent of the Earth's crust is composed of iron making it the fourth most abundant element. [6] Globally, iron ore is most commonly found in banded iron formations (BIFs) in the

获取价格

Iron ore - BHP

How is iron ore mined? From pit to port, our iron ore undergoes a series of processes before export. First, we explore the geology of the region to find the best iron ore prospects for our operations. Once the ideal site has been chosen, the ore is drilled and blasted. It is then transported to the primary crusher for processing.

获取价格

Iron Ore: Mineralogy, Processing and Environmental Sustainability ...

2021/12/2 Iron Ore: Mineralogy, Processing and Environmental Sustainability, Second Edition covers all aspects surrounding the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world's largest trillion-dollar-a-year metal market and is the backbone of the global infrastructure. The book explores new ore

获取价格مصنع تصنيع الأسمنت الهنغاري الصغير بسعة 50 طن في اليوم في الهند

حجر محدد الجاذبية

تعدين البوكسيت في اندونيسيا

المناشر المحمولة مقابض

تانتاليتي التعدين افريقيا

الصحافة الطين الطين الجرانيت

قوائم أسعار المحاجر عبر النهر

كسارة المحجر 600 طن ساعة

التعدين الواقي للسلامة

ما هي عيوب الفحم

قسم تعدين هندسة القاهرة

طحن مصنعين كسارة الدولوميت

إلى 100 طن ساعة محطة كسارة ناوا

الرقم مطحنة الكرة

زيارات إلى محطة كهرباء دادري من قبل الطلاب

التعدين و متناهية الصغر طحن

أفضل معدات كسارة المحجر المكسيك

كسارة للبيع في المملكة العربية السعودية

كيفية بدء الأعمال التجارية الحجر سحق في زامبيا

قائمة أسعار محطات الكسارة الإجمالية

آلة طحن نموذج db zz

خارطة شفاعمرو منطقة الكسارة

تأثير سحق سعر المصنع المحمول

موردو معدات صب الرمل

مزود خدمة الإنترنت في مطحنة الخور

الثابت والدوار مصنع

حول لدينا

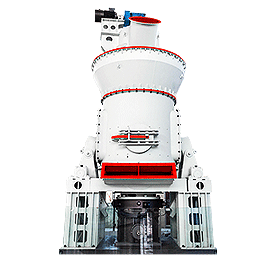

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20