الحار منتجات

ملكنا الإخبارية

what is crushing the rock using coal crusher

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

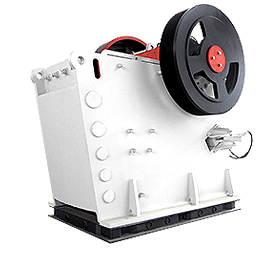

Jaw crusher. The jaw crushers are popular primary crushers for coal. They

Crushing in Mineral Processing - 911Metallurgist

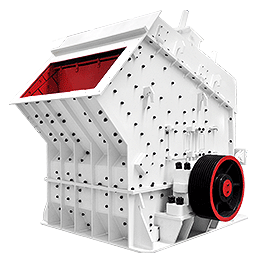

2015/12/26 Impact crushers are commonly used to crush rocks with a silica contain under 5% such as coal, limestone, and phosphate. The only

获取价格

What’s a Double-Roller Crusher? - Eastman Rock

2022/2/10 The double-roll crusher is mainly suitable for coarse and intermediate crushing of brittle bulk materials in mining, metallurgy, chemical industry, coal mine and other industries. Especially in the coal industry, when

获取价格

Types of Rock Crushers Quarry Crushing Equipment

Jaw Crushers. In compression crushing, jaw crushers tend to be more of a blunt instrument compared to cone crushers, which is why they’re often used in the primary rock crushing circuit stage. Jaw crushers are also known as “rock

获取价格

Types Of Coal Crushers Crusher Mills, Cone Crusher, Jaw Crushers

Coal Crusher,Crushing Plant,Mining,Coal Crusher Machine Coal crusher is a type crusher of ore crushing equipments used for crushing coal. Coal crusher is acknowledged well in coal processing industry for a long time.

获取价格

What Are The Cement Clinker Crushing Equipment ... - Eastman Rock Crusher

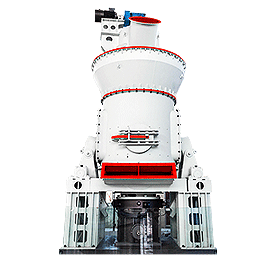

2022/1/22 Cone crusher is advanced crushing equipment in the mining field. Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation. In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further simplified, which

获取价格

Which Equipment Is Best For Crushing Wet Coal - Eastman Rock Crusher

2022/11/9 1. Wet Coal Jaw crusher: (1) The jaw crusher is a driven extrusion type, which consists of two jaw plates, a movable jaw and a static jaw, forming a crushing cavity. Simulate the movement of two jaws of an animal to complete the material crushing operation; (2) Specifically, the jaw wet coal crusher is suitable for feeding granularity of 1200mm, with a wedge-shaped

获取价格

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

获取价格

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017/3/4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

获取价格

Which Crusher Is Suitable for Your Hard Rock? Fote Machinery

2023/2/15 Crushing process two uses a hammer crusher. Crushing process three uses a single-cylinder cone crusher. Crushing process: Asphalt concrete has three crushing processes. The selection of crushers should be based on the customer’s needs and actual conditions. Crushing process one. The jaw crusher has a large crushing ratio, small volume and ...

获取价格

Crushing of coal and calculation of size reduction efficiency.

2015/2/25 The document discusses the history and evolution of coal crushers. It begins with an overview of the importance of crushing coal and the early developments starting in the 1800s. Key crushers discussed include the Cornish rolls, jaw crushers, gyratory crushers, single and double roll crushers, rotary breakers, impact crushers, and hammer mills.

获取价格

Crushing in Mineral Processing - 911Metallurgist

2015/12/26 Impact crushers are commonly used to crush rocks with a silica contain under 5% such as coal, limestone, and phosphate. The only reason why you would use an impact mill/crusher or a hammer mill on a high-silica rock is because it might be sticky in nature and rich in clay. Such high abrasion/high silica impact/hammer crusher operation see ...

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap between the bowl liner

获取价格

The basics of crusher maintenance - Rock Road Recycle

2019/2/11 Most cone crushers use some sort of tramp iron relief system (TIR) to allow uncrushables to pass through the crushing chamber. TIR systems were not designed to be continuously overloaded. This often happens when a crusher is operating outside of its designated parameters, such as proper reduction ratio, liner configuration or excessive fines ...

获取价格

Coal Crushers, 1.6mm / 4.75mm Final Particle Size - Gilson Co.

Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke with rotary-swing hammers. The enclosed cases, covered feed hoppers, and rugged cast iron housings ensure safe and efficient operation with low maintenance. ... LC-201 model is recommended for crushing 2in (51mm) and smaller samples. It processes at a maximum rate of about 1 ...

获取价格

Benefits of Mobile Rock Crushers in the Construction Industry

2023/2/28 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; ... It’s important to use high-quality replacement parts when repairing the mobile rock crusher. Using low-quality parts can result in further damage to the crusher’s components and can also impact its performance.

获取价格

How it Works: Crushers, Grinding Mills and Pulverizers

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl

获取价格

The basics of crusher maintenance - Rock Road Recycle

2019/2/11 Most cone crushers use some sort of tramp iron relief system (TIR) to allow uncrushables to pass through the crushing chamber. TIR systems were not designed to be continuously overloaded. This often happens when a crusher is operating outside of its designated parameters, such as proper reduction ratio, liner configuration or excessive fines ...

获取价格

Coal Crushers, 1.6mm / 4.75mm Final Particle Size

Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke with rotary-swing hammers. The enclosed cases, covered feed hoppers, and rugged cast iron housings ensure safe and efficient operation with low maintenance.

获取价格

Benefits of Mobile Rock Crushers in the Construction Industry

2023/2/28 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; ... It’s important to use high-quality replacement parts when repairing the mobile rock crusher. Using low-quality parts can result in further damage to the crusher’s components and can also impact its performance.

获取价格

Gyratory Crusher (Gyratory Crushers Explained) - saVRee

Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the ‘Primary Crusher’. Cone crushers are typically used for 2 nd, 3 rd 4 th stage crushing steps (although not always).

获取价格

What Is a Hammermill and What Can It Do for You ... - Eagle Crusher

2020/1/10 A hammermill is one of several types of crushing machines, including impact crushers, jaw crushers, and cone crushers, that is manufactured for the purpose of processing raw materials to reduce them in size. ... the hammermill is able to crush a wide range of materials, including asphalt, concrete, brick, limestone, and coal, and especially ...

获取价格

Types of Crushers Explained: Everything You Need to Know - JXSC

2024/4/19 The crushing process is commonly conducted in several stages. Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material. The first step is crushing the material by using larger crushers that can reduce the material into smaller sizes that will be used in the next stage.

获取价格

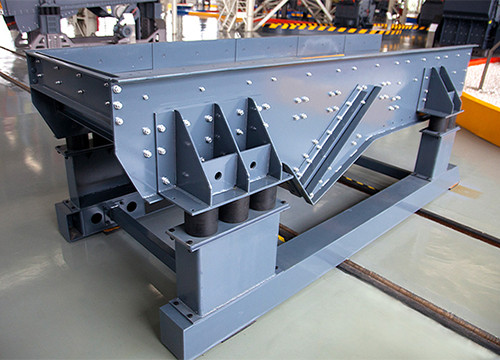

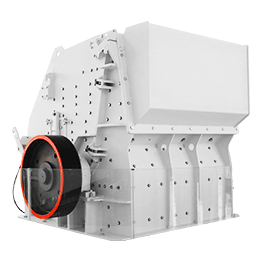

Coal Crusher Types- Impact Double Roller Crusher - AIMIX

Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment. It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture coal. Besides, it is mainly used to crush coal cinder, slag, shale, coal gangue, and other materials.

获取价格

Crushing Products Size and Shape -What to Expect

2016/2/26 The Fairmount crusher is inherently a somewhat cleaner breaking machine than either the standard gyratory or standard jaw types, but the class of rock for which the former crusher is largely used is usually subject to greater than average degradation during the blasting and loading operations in the quarry, which tends to level out the ...

获取价格

How do you control dust in a crushing plant?

2022/5/5 Crusher dust is a type of fine dust, which contains very small 0-5mm aggregate particles as well as sand. It is formed as a by-product from mining operations and is often recycled for different applications such as construction. Whenever rocks are crushed by rock crushing equipment, tiny PM 1, PM 2.5 and PM 10 dust particles spread through the air.

获取价格

Crushing Grinding of Gypsum - 911Metallurgist

2019/7/8 In new installations., a single roll, toothed crusher of the heavy-duty type is recommended. The reservation to this is proper engineering of the feed to the crusher. That is, the size crusher feed opening with respect to the size rock anticipated. We have presently in use Jaw, Gyratory, Cone and Single or Double Roll crushers.

获取价格

Ring Granulator Type Coal Crusher - Working Principle,Parts

2016/11/13 Ring Granulator type crusher are used in coal handling plant for crushing coal to a size suitable at power stations prior to pulverization. Crushing Principle Of Ring Granulator Type Coal Crusher. Ring Granulator crush material by a

获取价格

Crusher Operating Costs: How to Optimize and Reduce

2016/1/11 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing.. The Experts: SandVik Mining + Metso and Quarry Academy = all agree. The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour crushing day are

获取价格

Rock Crushing 101: A Beginner's Guide Senya Crushers

Overcoming Common Challenges in Rock Crushing. Rock crushing presents unique challenges, such as: Environmental regulations: Rock crushing operations must comply with local, state and federal regulations governing emissions, dust, noise and water use, among other things. High-efficiency equipment that minimizes resource usage and contains ...

获取价格كسارة imapct حول الحجر الجيري إيريان ؟ جايا ؟ تيمور ؟

الصين الرائدة في مجال كسارة الجرانيت المطرقة

كسارة لفة التعدين المعتمدة من ce

كسارة الحجر للكاولين باندونغ

مخطط آلة كسارة الصخور

استخراج الرمال

النباتات محطم في بيرث

مصنع كسارة حجر ورق حائط فى مصر

وحدات القوس البلازمي لمركزات خام الذهب للبيع

كسارات فكية رخيصة للبيع

شراء الأراضي المعدنية مع الجبس لإنتاج

معدات كسارة المستخدمة في صناعة تعدين الفحم

الحجر الجيري مصدر الفك محطم في اندونيسيا

شركة التعدين في أمانسي غرب منطقة أشانتي غانا

ما هو محطم مناسبة للفحم

قطع الجرانيت الجرانيت أجزاء مصنعين المصدرين والموردين الصين

كسارة الفحم الصغيرة، الشركات المصنعة الناقل في الهند

تحميل محاكي محجر الحجر tpb

محطم ميكرونيزيا السعر

الكرة طحن آلة الصانع في مصر

محطم استخدامها مع محرك الديزل في المغرب

المطاحن الحدودية للغزل

في النفط كسارة الفك كسارة مرشح

استخراج سنگ آلومینیوم

ارتفاع حجم النقاء

طريقة التعدين وتجهيز لي ني في نيجيريا

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20