الحار منتجات

ملكنا الإخبارية

brake system of a mill machine

Understanding SAG Mill Brake Systems an Exploration!

2023/8/7 Safety is increased as the mill cannot move once the brakes are engaged.

获取价格

Milling Machine Brake System - MAKESafe Tools

Milling Machine Brake System quantity. Add to cart. SKU: N/A Category: Safety Systems Tags: qty-discount, system-bundles. Description Specifications ... Milling Machine Brake and Motor Controller; 3-Button Control Panel on 5′ remote

获取价格

GEMCO Brake Systems Application Guide - GemcoDirect

Gemco Industrial Brakes stop virtually any type of industrial machine. Applications such as

获取价格

Mining Mill Braking Technologies - Altra Industrial

The VMS-DP brake caliper (see Figure 3) weighs 1850kg and is capable of producing a braking force of 737kN each (940kN clamping force). It is a spring applied, hydraulically released unit which requires the mill flange (braking

获取价格

23 Parts of Milling Machine and Their Functions

9. Quill Feed Rate Selector: ( Parts of Milling Machine ) A Quill feed rate selector is a quill selector that is utilized to adjust or change the speed of the Quill in inches per revolution (IPM). The accessible setting on the standard machine is

获取价格

Power Drawbar Precision Matthews PM-728VT

The Power Drawbar is a CNC-class pneumatic system that automates the task of loosening and tightening the drawbar when changing a tool on a milling machine. This greatly expedites the tool changing process and adds a great deal of

获取价格

Steel Mill Crane Hoist Brakes - Hindon

Hindon’s mill duty brakes are the ideal solution for steel mill operators looking to upgrade their crane brakes.In addition to supporting customers with crane service brake retrofits, Hindon also has extensive experience with both new and retrofit projects involving emergency hoist brakes in steel mill environments.. Not only does Hindon provide the highest quality, most reliable,

获取价格

Mill Balancing: Why Is There a Notch in My Brake Rotor? - PowerStop Brakes

If an imbalance is present, the machine uses a milling blade to notch the “heavy” side of the rotor on the edge. The notching is placed between the friction contact areas to avoid interference with the brake pads during operation. The machine mills out just enough material that the weight of the milled material equals the amount of imbalance.

获取价格

SERIES I MILLING MACHINES - Massachusetts Institute of

MILLING MACHINES Revised: August 29, 2005 Manual No. M-450 Litho in U.S.A. ... machine is operating in, 60 to 500 low range, 500 to 4200 high range. 2-2 M-450 Figure 2.2 - High-Low Range Switch A TP5286 Figure 2.3 - Variable Speed Dial TP5287 B. SPINDLE BRAKE Spindle Brake “C”, Figure 2.4, can be moved in either direction to stop spindle ...

获取价格

Can I turn brake rotors on milling machine? : r/Machinists - Reddit

The front brakes on my Harley are feeling out of round. When I pull the front brake I get the studdering as it's grabbing and then a low spot then grabbing again. I don't have a lathe but I have a damn nice milling machine from the 30's passed from Grandpa to dad to me.

获取价格

A Simple Guide to Lathe Brakes - AMBI-Tech Brakes

2021/8/23 Learn how a lathe brake works and what you need to know about maintaining them below. Types of Lathe Brakes. While a brake on a lathe works to stop the machine from turning, not all brakes function the same way. Modern lathes contain multiple types of brakes to provide longevity to the machine and to perform under different conditions.

获取价格

Bridgeport Spindle Brake Replacement - The Home Shop

2007/2/22 Where can I find a procedure for replacement of the spindle brake on a Bridgeport mill? The machine has a variable speed 2J head. The spindle is free but from all appearances the brake shoes are worn out and probably need to be replaced. ... Actually the brake shoes last a long time on a mill. Much longer than you may think.

获取价格

10 Troubleshooting Common Brake System Problems

1. The Brakes are not Working Well. Brake failure is one of the most dangerous scenarios that can happen when driving. Thankfully, car manufacturers have taken this into account and equipped their cars with fail-safes to prevent complete brake failure from happening. Modern cars have a redundant hydraulic system that can provide fail-safe braking if one system fails and a

获取价格

Clausing 8520 owners, Any tips or tricks? - Practical Machinist

2009/5/21 Hello from the newbie, I just brought home my Clausing 8520 on Sunday and after a good scrubbing it seems I actually have found a nice, lightly used machine that was hidden under a layer of grunge. I have a few maintenance items to address but overall it is in great shape. The original motor was...

获取价格

Design, Analysis Manufacturing of Disc Brake

milling machine cutter, and a reciprocating adjustable workbench that mounts and feeds the work piece. • A CNC milling machine is the most flexible milling machine operated by a computer. The spindle can move in all three directions, and the table can rotate 360 degrees, making it an enhanced version of the bed type milling machine.

获取价格

Gemco Industrial Brakes - AMETEK FACTORY AUTOMATION

Gemco Industrial Brakes stop virtually any type of industrial machine. Applications such as steel mills, indoor and outdoor bridge cranes, gantries, heavy-duty cranes, high-duty cycle cranes, lock and dam projects, stacker reclaimers, and commercial laundry equipment are just some of the uses for our industrial brakes.

获取价格

Vertical Milling Machine - Argonne National Laboratory

The Milling Machine uses a rotating milling cutter to produce machined surfaces by progressively removing material from a work piece. The vertical milling machine also can function like a drill press because the spindle is perpendicular to the table and can be lowered into the work piece. Mill Study Guide P.1 Advanced Photon Source

获取价格

Clausing 8520 owners, Any tips or tricks? - Practical Machinist

2009/5/21 Hello from the newbie, I just brought home my Clausing 8520 on Sunday and after a good scrubbing it seems I actually have found a nice, lightly used machine that was hidden under a layer of grunge. I have a few maintenance items to address but overall it is in great shape. The original motor was...

获取价格

Design, Analysis Manufacturing of Disc Brake

milling machine cutter, and a reciprocating adjustable workbench that mounts and feeds the work piece. • A CNC milling machine is the most flexible milling machine operated by a computer. The spindle can move in all three directions, and the table can rotate 360 degrees, making it an enhanced version of the bed type milling machine.

获取价格

Gemco Industrial Brakes - AMETEK FACTORY

Gemco Industrial Brakes stop virtually any type of industrial machine. Applications such as steel mills, indoor and outdoor bridge cranes, gantries, heavy-duty cranes, high-duty cycle cranes, lock and dam projects, stacker reclaimers, and

获取价格

Vertical Milling Machine - Argonne National Laboratory

The Milling Machine uses a rotating milling cutter to produce machined surfaces by progressively removing material from a work piece. The vertical milling machine also can function like a drill press because the spindle is perpendicular to the table and can be lowered into the work piece. Mill Study Guide P.1 Advanced Photon Source

获取价格

Understanding SAG Mill Brake Systems an Exploration!

2023/8/7 Safety is increased as the mill cannot move once the brakes are engaged. Horsepower and Flange Diameter; The range of power for mills; a SAG mill can have from 32,000 horsepower [23.8MW] to 47,000 horsepower [ 35MW ]. This staggering amount of power underscores the importance of an efficient brake system.

获取价格

3 Effective Methods for Tramming a Milling Machine

2020/2/4 Tramming is a fundamental process in any machine shop equipped with manual milling machines. The process consists of checking and adjusting the squareness of the mill to the top of the machine table, AKA the tram. ... Edge Technology Pro Tram System . Which is the best method? ... I use a new car or truck brake rotor. It’s flat within .001 ...

获取价格

Safeguarding Choices for Milling Machines - Rockford Systems, LLC

2016/8/1 Rockford Systems encourages all employers to exceed minimum requirements and abide by the best safety practices found in ANSI B11.8-2011 (R2008) for drilling, milling, and boring machines, and ANSI B11.23-2002 (R2007) for machining centers. The key to employee safety is to observe best safety practices at all times.

获取价格

9" x 49" New Bridgeport Mill Series 1 - Worldwide Machine Tool

A new Bridgeport Series 1 standard vertical milling machine is built with inch screws and Dials and a R-8 Spindle. Every new Bridgeport milling machine for sale also comes with hand scraped chrome ways and gibs, one-shot Lube and is available in 230V 60Hz, 208V 60Hz or 460V 60Hz electrics. Worldwide Machine Tool will provide you with a complete ...

获取价格

Section 6, Unit 1: Introduction to the Vertical Milling Machine

spindle brake. Choose matching term. 1. Machinists' maintenance responsibilities should include lubricating the vertical milling machine using what type of system? How frequently should this be done? 2. A _____ locks the elevating crank in place after positioning the knee. 3.

获取价格

Anyone machine brake rotors on lathe or mill? : r/Machinists

Anyone machine brake rotors on lathe or mill? I was going to change my brakes soon and I was thinking of cutting my own rotors but I'm scared runout will still persist afterwards. I know the machines that mechanics use cut from both sides of the rotors to eliminate all runout. ... We seriously need to have a buddy system for brain dead easy ...

获取价格

J-Head Brake Shoe Replacement - HW

J-Head Brake Shoe Replacement. 1. Turn off and lock out the power to the mill. 2. Remove the power from the source to the drum switch. 3. Loosen the motor and lower the Drive Belt below the Motor Pulley.

获取价格

A Review of Sensor System and Application in Milling Process for

2014/3/15 This study presents a review of the state-of-the-art in sensor technologies and its application in milling process to measure machining signal for Tool Condition Monitoring (TCM) systems.

获取价格

LMV - Sharp Industries

10). Pulling the brake lever up after it is engaged can lock the brake. Caution: Be sure the brake is in neutral before starting the spindle. c. Installation of Collet: 1. Raise the spindle all the way up. 2. Insert collet, being sure the keyway lines up with the pin in the spindle. 3. To tighten, turn the drawbar clockwise while brake is engaged.

获取价格

General Excello 602 Questions - Practical Machinist

2006/10/17 I have two of these, one has a manual knee, the other uses a ball screw jack with servo motor + brake and pneumatic counter balance for initial positioning with VFD control of the 3ph spindle. ... 6" of quill feed with a smooth clutch instead of a pop-out system. Wider table than BP. ... Excello XLO 602 Vertical Milling Machine Ram Turret ...

获取价格كسارات المطرقة للبيع

شركات التصنيع في كلكتا

درج بالون البني

youtube video batu Mesin crusher

آلات تكسير لكسارة الصخور

آلة الرمال الحديد الاسفنجي

شبكة تهتز مجعد 40 × 40 × 6 مم

غسل الرمال المصنوعة في الصين

كسارة فكية pe x للبيع الفلبين كسارة فكية pe x

مصنع محجر رمل السيليكا للبيع ليبيا

كيفية بدء الأعمال التجارية محجر في ولاية كيرالا

تخصص فني كلية الطلاب في التعدين في عدة نقاط من الممارسة تعدين الفحم

خام خلع الملابس خام النباتات الرملية في ياوندي

آلة شريط كسارة

آلات لمحاجر الجرانيت

تعدين الفحم بوينو الجزائر

محجر مطرقة مطرقة مطحنة للبيع

الشركة المصنعة للمعدات مصنع الاسمنت مصنع في الهند

صناعة تعدين الذهب في جنوب أفريقيا التحديات الرئيسية

حجر صغير لبيع

الصين الرماد المتطاير خط إنتاج الطوب

جيا لتسوية القوة نجاح باهر كاتا

مصنع المطرقة gt

حمض المضادة للتآكل الثقيلة تركز المعادن والمطاط المكره

قیمت شن و ماسه آنگولا

نظم استعادة خام التنجستن

حول لدينا

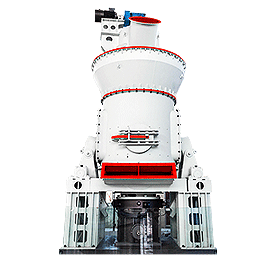

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20