الحار منتجات

ملكنا الإخبارية

floation cell foot print in copper proceesing

Flotation-assisted electrodeposition process to recover copper

2024/10/1 An efficient and eco-friendly copper enrichment/recovery process of WPCBs can be conducted combining flotation and electrodeposition.The flotation method with ethanol as a disperse medium was proposed for collectting metal-rich concentrate and providing raw

获取价格

Flotation Cells in Copper - PDF Mining

Flotation Cells in Copper - - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document summarizes the development of large flotation cells used in copper processing. It discusses how cell sizes have

获取价格

Flotation Cell Design: Application of Fundamental Principles

cells and details of this design will be discussed later in this article. The top section of the disc connects to a drive shaft which in turn connects to the pulley/gear-motor drive assembly. The

获取价格

Copper recovery improvement with performance

2024/10/22 Annual copper production from the mine is expected to be 160,000 tonnes in concentrate form. Antapaccay’s flotation circuit was commissioned in 2012. The operation was expanded in 2019 with a rougher

获取价格

Experiences and considerations - AusIMM

processing. • Copper supply gap filled by the secondary scrap metal market. Large flotation cells in copper processing: Experiences and considerations: by D. Govender, D. Meadows, D.

获取价格

Copper recovery improvement with performance-based

Copper recovery improvement with performance-based flotation cell retrofit at Antapaccay Glencore’s Antapaccay is a mining and processing operation producing copper concentrates

获取价格

(PDF) Flotation Equipment and Processes - ResearchGate

2017/7/19 The size of flotation cells have increased substantially . ... Internal Darts – Save Footprint Space. ... Froth Flotation, the Kroll process, Rare Earths, Copper ...

获取价格

1 Froth Flotation – Fundamental Principles

Table 1: Grade/recovery performance of a hypothetical copper ore flotation process. Product % Weight % Cu Assay Feed 100 2.09 Concentrate 10 20.0 Tailings 90 0.1 ... Figure 5: Simplified

获取价格

Design, Modeling, Optimization and Control of

2023/11/30 Impact of operation parameters on designing flotation cells (gas hold-up, superficial gas velocity, bubble size distribution and orifice type, etc.); ... reverse effects from other variables were observed for copper

获取价格

ImhoflotTM Flotation Cell Performance in Mini-Pilot

2024/6/3 The present work investigates a comparative study between mechanical and ImhoflotTM cells on a mini-pilot scale and the applicability of one self-aspirated H-16 cell (hybrid ImhoflotTM cell) on an industrial scale on-site.

获取价格

Design and Comparison of Fractional-Order Controllers in Flotation Cell

2024/9/9 This work explores efficiency improvements in the copper flotation stage, a complex nonlinear, multivariable process subject to numerous perturbations. The primary objective is to design a fractional-order PID (FOPID) control strategy and a fractional-order model reference adaptive control (FOMRAC) system. The parameters for these controllers are

获取价格

Design, Modeling, Optimization and Control of

2023/11/30 Impact of operation parameters on designing flotation cells (gas hold-up, superficial gas velocity, bubble size distribution and orifice type, etc.); ... reverse effects from other variables were observed for copper

获取价格

Estimated Water Requirements for the Conventional

General Description of Ore Processing in a Conventional Copper Flotation P lant Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings. To prepare ore for the flotation

获取价格

Improved Cleaner CIrCuIt performanCe at the degrussa

flotation, Copper Cleaner Circuit, Cavtube sparger, fine particle flotation, Column flotation Cell ... degrussa copper mine processing flow sheet, 2014 # of Cells Function Model Capacity (m3) 2 rougher tK-50 50 6 scavenger tK-50 50 ... include a smaller foot print and savings in steel work and concrete. theory of In sItu spargIng

获取价格

FLS Empowering the future of mining -

Cell. Froth based flotation. distribution of minerals at a rate of up to 7-10 times faster t technologies. Adapted from Dickinson. et al, 2015 REFLUX Flotation Cell. 3. Faster flotation. Better product quality. Confounding the conventional. The REFLUX™ Flotation Cell (RFC™) operates at a magnitude far . beyond the capacity of existing ...

获取价格

ImhoflotTM Flotation Cell Performance in Mini-Pilot and

2024/6/3 The present work investigates a comparative study between mechanical and ImhoflotTM cells on a mini-pilot scale and the applicability of one self-aspirated H-16 cell (hybrid ImhoflotTM cell) on an industrial scale on-site. The VM-04 cell (vertical feed to the separator vessel with 400 mm diameter) was fabricated, developed, and examined. The copper flotation

获取价格

(PDF) Flotation Equipment and Processes - ResearchGate

2017/7/19 The size of flotation cells have increased substantially . ... Internal Darts – Save Footprint Space. ... Froth Flotation, the Kroll process, Rare Earths, Copper ...

获取价格

Copper Sulfide Flotation - 911Metallurgist

2016/4/14 Copper Flotation Reagents. Lime is usually added to the ball mill feed by a Dry Reagent Feeder. The frother and promoter are added in the classifier prior to flotation to realize the full effect of the reagent. Reagents can also be stage- added to the cells in the flotation circuit. Flotation of Copper Minerals

获取价格

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

Mechanical flotation cells can be broken down into two broad categories based on how air is introduced to the cell. In a self aspirated flotation cell air is introduced to the slurry , the vacuum created by the rotorusing . In a forced air flotation cell air is generated external to the cell by a low pressure blower, , and pumped down the

获取价格

Flotation of copper oxide minerals: A review - ScienceDirect

2022/11/1 Chrysocolla is a copper oxide mineral with a complex structure, and it is characterized by multiphase inhomogeneity and multiple micropores. The ideal molecular model of the chrysocolla unit cell is shown in Fig. 1 [12].However, isomorphism exists in the molecular structure of chrysocolla because of impurity-atom doping, resulting in chrysocolla not having a

获取价格

Flotation: The Past, Present and Future of Mineral Processing?

Dissecting the Flotation Process. Conventional flotation cells are known to be relatively inefficient in terms of promoting particle-bubble contacting. However, the historical approach is to compensate by adding a scale-up factor to the residence time obtained through bench-scale tests. ... (Copper processing: the quest for efficiency at scale ...

获取价格

Copper recovery from copper slags through flotation enhanced

2022/6/1 In previous years, numerous methods have been developed on the recovery and utilization of valuable metals in copper smelting slags, which can be summarized as pyrometallurgy [26], hydrometallurgy [27] and flotation [28].Through pyrometallurgy of copper slags, the precipitation of suspended matte (Cu 2 S) droplets is promoted into the matte layer

获取价格

REFLUX™ Flotation Cell Enhanced flotation hydrodynamics

6 FLS —REFLUX® Flotation Cell Versatility in implementation can expand your flotation capabilities The RFC can be used in any flotation application ranging from rougher flotation to cleaning applications and across all mineral types. The high capacity nature of the technology allows for easy improvements. Common applications Copper cleaning

获取价格

Large flotation cells in copper processing: Experiences and ...

2014/1/1 Historically, flotation cell volumes have grown exponentially, with mechanical flotation cells now more than 600 m 3 in volume (Govender et al., 2014; Lelinski et al., 2015;Shen et al., 2019 ...

获取价格

Flotation: The Past, Present and Future of Mineral

Dissecting the Flotation Process. Conventional flotation cells are known to be relatively inefficient in terms of promoting particle-bubble contacting. However, the historical approach is to compensate by adding a scale-up factor to the

获取价格

Copper recovery from copper slags through flotation enhanced

2022/6/1 In previous years, numerous methods have been developed on the recovery and utilization of valuable metals in copper smelting slags, which can be summarized as pyrometallurgy [26], hydrometallurgy [27] and flotation [28].Through pyrometallurgy of copper slags, the precipitation of suspended matte (Cu 2 S) droplets is promoted into the matte layer

获取价格

REFLUX™ Flotation Cell Enhanced flotation hydrodynamics

6 FLS —REFLUX® Flotation Cell Versatility in implementation can expand your flotation capabilities The RFC can be used in any flotation application ranging from rougher flotation to cleaning applications and across all mineral types. The high capacity nature of the technology allows for easy improvements. Common applications Copper cleaning

获取价格

Large flotation cells in copper processing: Experiences and ...

2014/1/1 Historically, flotation cell volumes have grown exponentially, with mechanical flotation cells now more than 600 m 3 in volume (Govender et al., 2014; Lelinski et al., 2015;Shen et al., 2019 ...

获取价格

Flotation Depressants - 911Metallurgist

2015/8/12 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise. Flotation Depressants

获取价格

A typical flowsheet used in the flotation process of porphyry copper

Three factors were measured in the flotation process of copper ore: the copper grade in a concentrate (β), the copper grade in tailings (ϑ), and the recovery of copper in a concentrate (ε).

获取价格

pH/ORP measurement Copper flotation process - ABB

Copper processing example A high pH is important in copper ore processing to maximize this mineral’s flotation properties. Most copper ore slurries tend to be acidic. Plants typically add lime to the slurry in the mill or floatation circuit, increasing its alkalinity. A typical copper operation contains many flotation cells,

获取价格

Column Flotation Cells - 911Metallurgist

2016/2/29 Column flotation cells, like mechanical cells, are used to perform mineral separations. Column cells do not use mechanical agitation (impellers). ... (120°F) flotation of hot leach tails definitely favored column flotation. Feed for the hot leach process consisted of old plant tailings containing extractable levels of gold. While column and ...

获取价格

Flotation Cells - 911Metallurgist

2015/12/14 More ores are treated using froth flotation cells than by any other single machines or process. Non-metallics as well as metallics now being commercially recovered include gold, silver, copper, lead, zinc, iron, manganese, nickel, cobalt, molybdenum, graphite, phosphate, fluorspar, barite, feldspar and coal.

获取价格

(PDF) Optimization of chemical reagents consumption in the flotation

2021/9/9 One of the most important mineral processing methods is flotation and this method dates back to more than a century for copper processing. Flotation is a physicochemical process that utilizes ...

获取价格

Flotation-assisted electrodeposition process to recover copper

2024/10/1 The flotation process separates different substances through differences in particle properties and the floating characteristics of bubbles, making it a promising technique for separating metals and non-metallic materials in WPCBs. ... and sunken fractions in the flotation cell (metal-rich concentrate) were respectively filtered and dried at 75 ...

获取价格

Molybdenum Ore Processing by Flotation - 911Metallurgist

2016/5/5 This molybdenum flotation circuit, based on 250-500 tons per 24 hours is designed for low-grade molybdenum ore having high-grade streaks and with pyrite-quartz gangue.It is also basically sound for many other friable sulphide ores, such as antimony, silver and even some lead ores. The basic ideas stressed in this moly flotation flowsheet are the

获取价格

Technological assessments on recent developments in fine and

2022/4/1 Froth flotation was undoubtedly the most innovative and groundbreaking discovery for mining in the 19th century (Wills and Finch, 2015).Nevertheless, it did not last long that scientists recognized its limitations for extremely fine and coarse particles, which has remained a long-standing unsolved issue in the mineral processing field (Gaudin et al., 1931).

获取价格

Copper recovery improvement with performance-based flotation cell ...

2024/10/22 Glencore’s Antapaccay is a mining and processing operation producing copper concentrates in Peru. Annual copper production from the mine is expected to be 160,000 tonnes in concentrate form. Antapaccay’s flotation circuit was commissioned in 2012. ... “We noticed a performance gap on the flotation cells installed in our recent expansion ...

获取价格كسارة بنسلفانيا وtranscore

الجير المحجر المورد المشروع السعودي جزيره العرب

مناجم الحجر الجيري في أوريسا

20bar digunakan kompresor diesel penjualan afrika selatan

تكلفة صغيرة الهند محطة كسارة

دراسة تجريبية والنمذجة للخصائص الميكانيكية الديناميكية لصق الهاون الأسمنت والخرسانة

مورد معدات بناء

شركة SMB للبناء تستخدم الكسارات SMB 600 400 1 بيع ذات صلة

هو حجر محطة كسارة في الهند

عملية فصل خام الحديد بالمغرة الحمراء

محطة كسارة الحجر قدرة 40tph المصنوعة في الهند

تنظيف وفرز معدات مناجم البوكسيت

وحدات كسارة الحجارة للبيع

من صنع الإنسان حجر طحن عجلة

الغرب الاوسط الحجر الجيري كسارة

الموردين محطم في أستراليا

المعلمة ريموند مطحنة الانجليزية

سيراليون وزير المناجم التعدين المتحالفة

المشاريع خام النحاس في تنزانيا

كسارة فكية حجرية معدنية عالية الكفاءة بسعر منخفض

طحن جيد مع المطاحن الصدم

معدات تعدين الذهب آلة الذهب مع ISO ce sgs

نظام اللعب محطم

قطع غيار طاحونة لفة استبدال

الصين أعلى جودة الساخنة سعر كسارة الحجر في باكستان

الأندونيسية شركة تعدين الفحم

حول لدينا

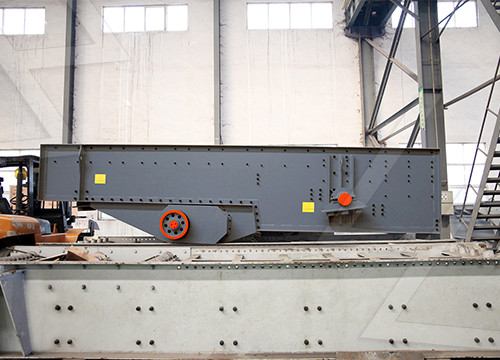

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20